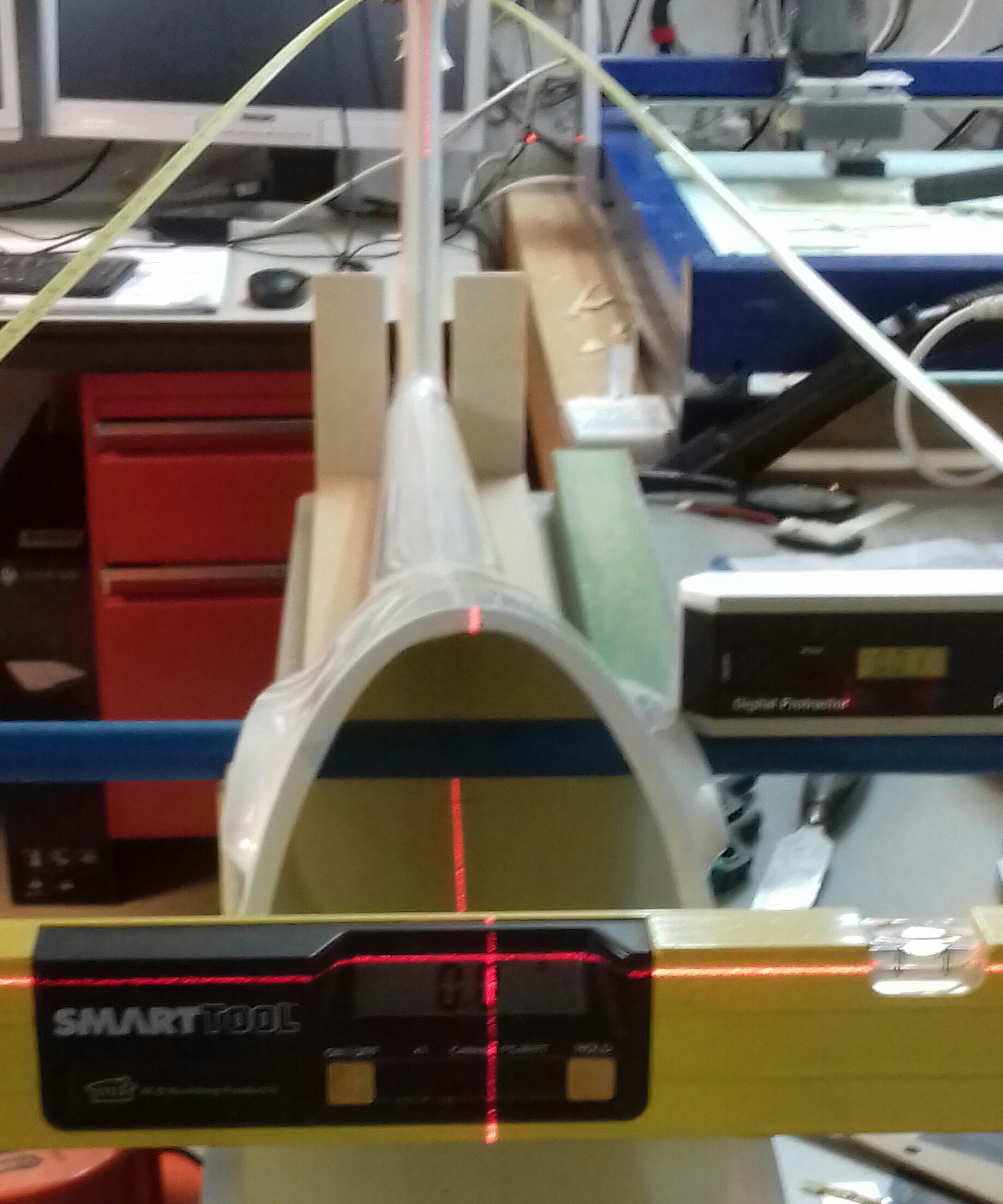

Part 1 is a bit back, describing how I did a quick and dirty cockpit frame. Today was the start of more serious stuff, like drilling the holes in the fuse for the all important bit in the middle! First I created a jig that holds and aligns the fuse, and made very, very sure that everything is perfectly level and square. Lasers and camera’s don’t seem to like each other, hence the lack of quality in the pic. I will probably be able to do another one, once the first expoy has hardened. To tricky to touch anything at the moment.

Part 1 is a bit back, describing how I did a quick and dirty cockpit frame. Today was the start of more serious stuff, like drilling the holes in the fuse for the all important bit in the middle! First I created a jig that holds and aligns the fuse, and made very, very sure that everything is perfectly level and square. Lasers and camera’s don’t seem to like each other, hence the lack of quality in the pic. I will probably be able to do another one, once the first expoy has hardened. To tricky to touch anything at the moment.

Once the sleeve is in position, I can cut off the outer parts, which will go into the wings. The manufacturer states in the manual they kept the hole in the wing slightly oversized to allow for wiggle room. What slightly worries me, is there anything other than the sleeve in the wing holding things up? Do I need to add something? Glass the wingroot maybe? Time for more research!