Author: Kees

-

Chocomel anyone?

Friend asked me to check an old tug, so there you go! All ready for the next generation of TugPilots. Of course with Jeti, we have the famous dual control system. (Note to Self, do post/store the manual somewhere safe.) Some day Real soon we need to replace those NiCads.

-

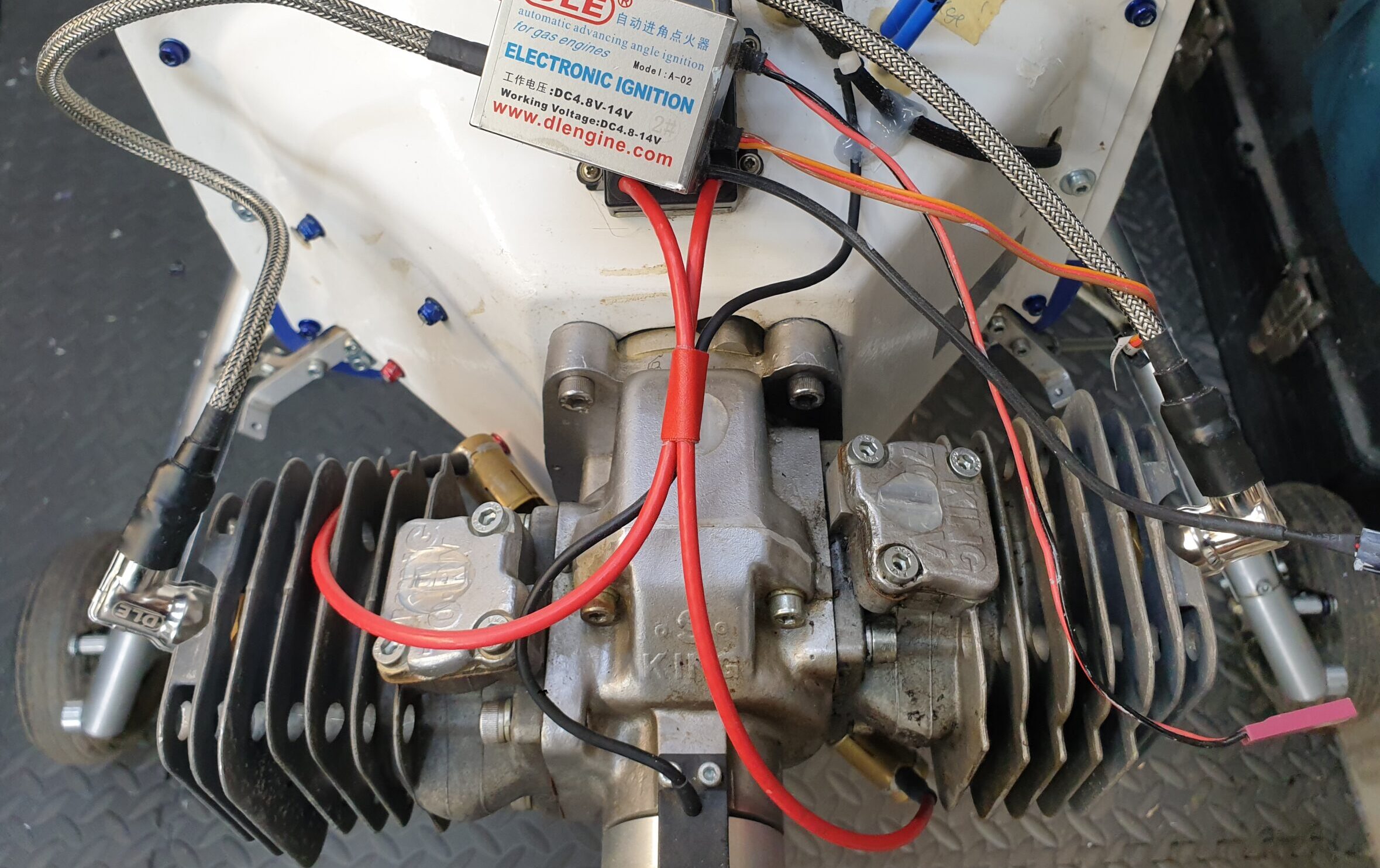

A tale of an unhappy King

This week I had the pleasure of finally (famous last words) sorting out a Wilga with a King140. For quite some time the engine would not start, then run irregularly, then on another day it was fine, in other words, it was all over the place. Of course I approached the problem with: 95% chance…

-

Where has everything from the last years gone?

Had some issues with the website (php being too old, template too old, plugins no longer supported) that caused some headaches. This, despite always keeping everything up to date. At some stage last year I restored a backup, that in hindsight was not a current one. Probably thought ‘just for testing’, I’ll put the good…

-

Surpise, surprise, it works!

After building a nicer box for the electronics, I used my Acrowot as the test-bed of choice, the motor mount is loose, the battery is 7 years old, but hey, just enough oomph for a test. Anyways, looking at the data, I am very happy. My receiver on the shed even picks up the signal…

-

Could not let it go..

It’s one of these things I knew I could fix, if only I would just concentrate. I’m talking about my almost nose to nose encounter with that heli-boy a while back. It sure did scare me, tell you that! Anyway, we now have the Technology, so next time, he will see me/us. The Technology is…

-

Busy busy making dust..

I’ve been sanding and plastering and sanding more and then some more and still there’s more to sand. All in an effort to make the ASK21 wing profile as accurate as I can. It’s a real effort, and very time consuming. The root section is the worst, especially the nose of the profile was not…

-

3D printer woes..

My bed was giving me problems. For ABS you need a bed temperature of at least 100 C. 110 is better. In the original design, all electronics are in the base of the printer, but with a 110 degree bed things were getting too comfy. That resulted in random interruptions of the print, even with…

-

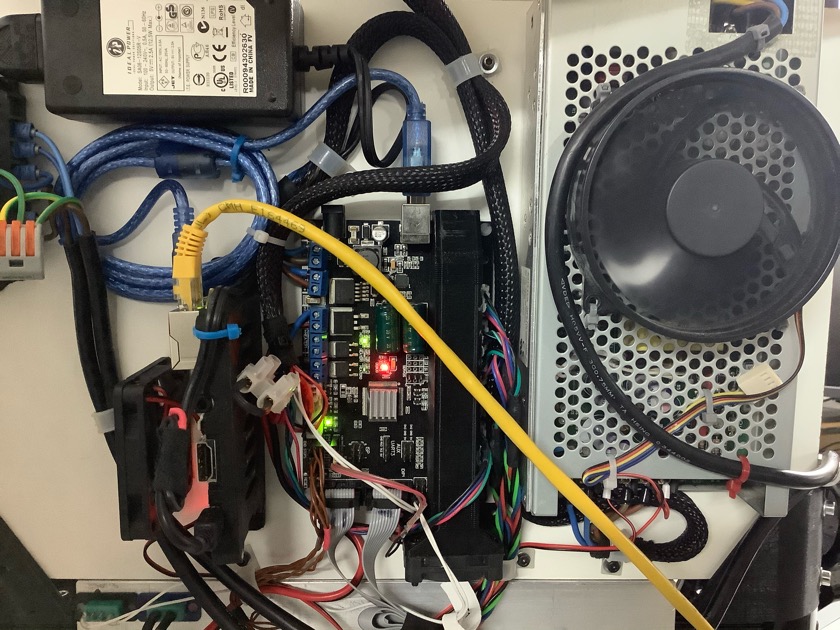

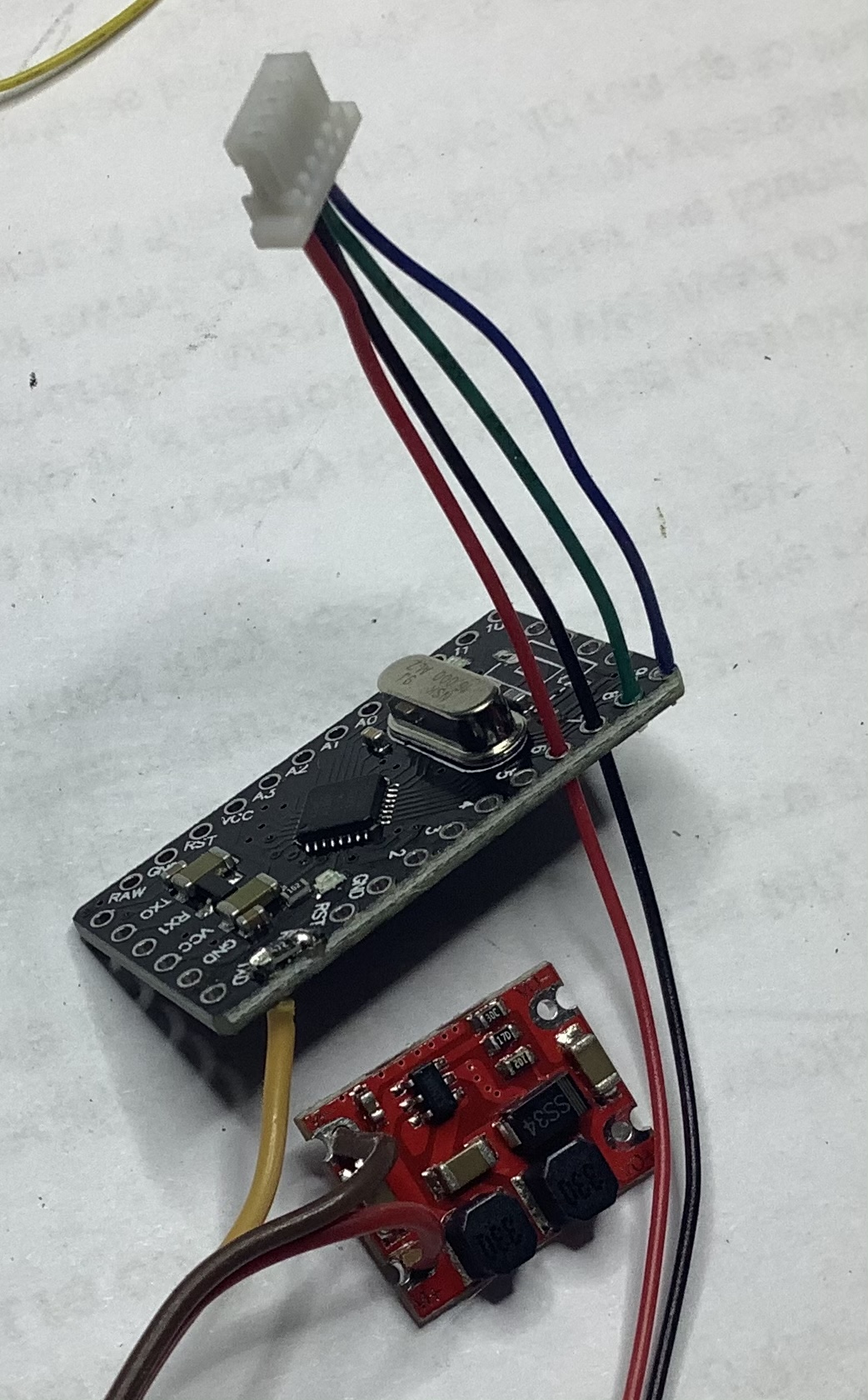

Playing with electronics again.

Nothing serious, trying to catch up on some loose ends. One of the fun things I tested today was seeing how low my input voltage can go before the output (5 Volt) collapses. The background to this is that initially when building Jeti sensors, I used step-down converters to allow the use of 2S battery…

-

Change of format

I’m going to make one post a week, and add all the stuff I do in this post. Unless I change me mind. I wondered how long I have been working on this: looks like first metal was cut in June 2019. Not bad. Before going too far I thought it would be a good…

-

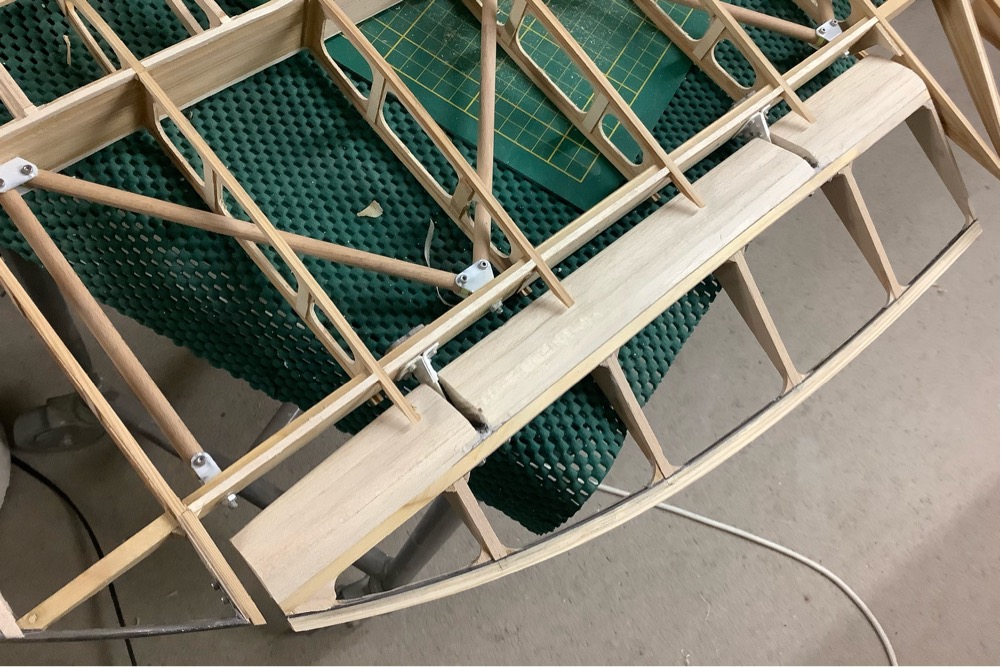

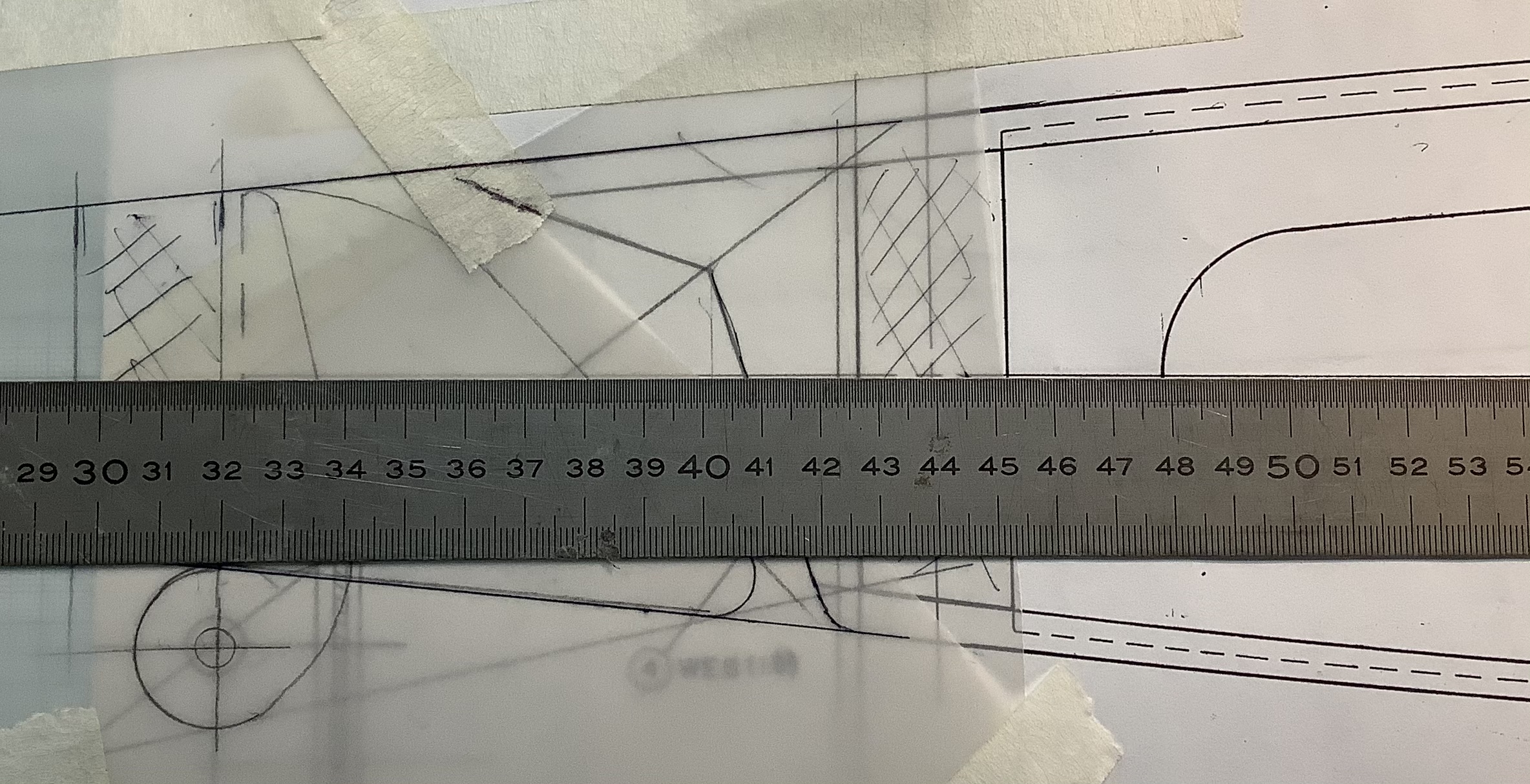

Ailerons again

Some of the drawings are not to scale, which is no problem if you build the full size version. A few important ribs are drawn full size, and from there it is easy to find the missing dimensions. Because the dimensions on a piece of paper are very hard to determine accurately, I found I…