Category: ASK21

-

Busy busy making dust..

I’ve been sanding and plastering and sanding more and then some more and still there’s more to sand. All in an effort to make the ASK21 wing profile as accurate as I can. It’s a real effort, and very time consuming. The root section is the worst, especially the nose of the profile was not…

-

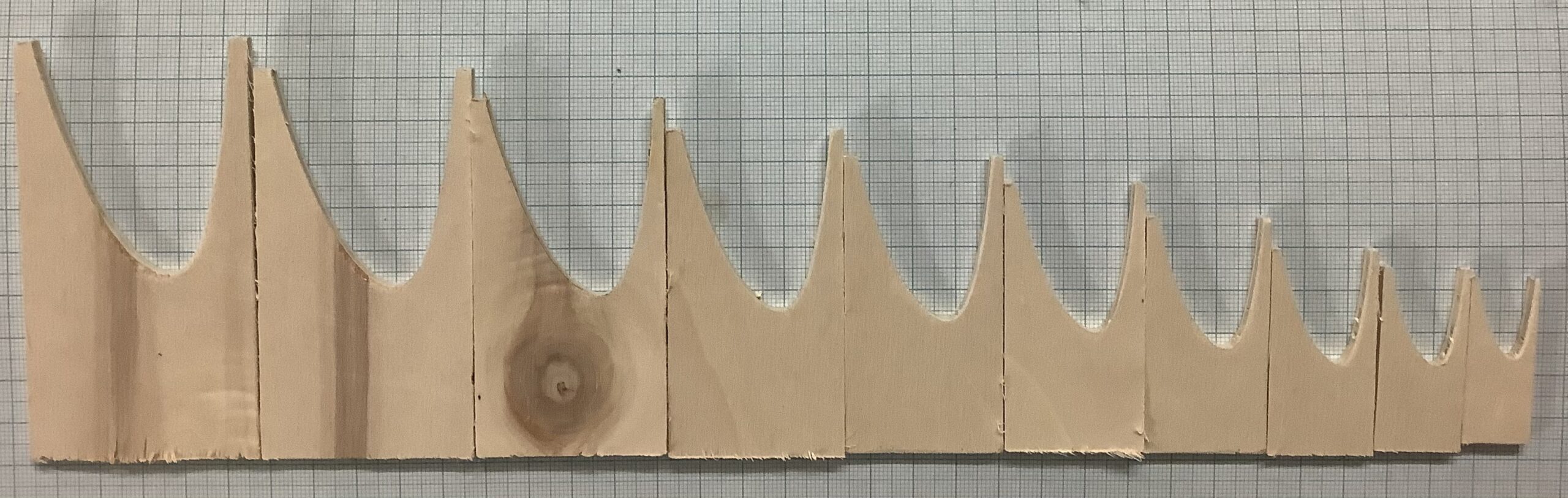

ASK21, lets start

I’ve been looking at it for too long, so let’s get going. As always, first things first. The wings are what keeps us up there, the rest is only there to keep the pilot dry and comfy. The kit I have was produced by Heinz Maassen Flugzeugbau. (I believe Heinz passed away early 2015) ….Die…