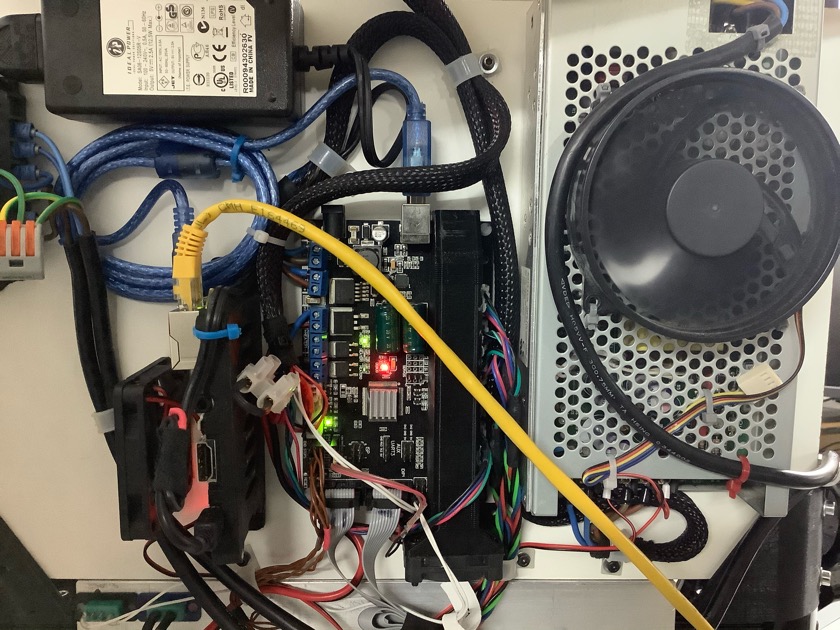

My bed was giving me problems. For ABS you need a bed temperature of at least 100 C. 110 is better. In the original design, all electronics are in the base of the printer, but with a 110 degree bed things were getting too comfy. That resulted in random interruptions of the print, even with added fans in the bottom Since I ran out of PLA and ASA filaments, and only had ABS left, I decided to fix the problem properly. So I stripped everything and rebuild the whole thing. It was only a weeks work, but I am pretty confident things are working better now.

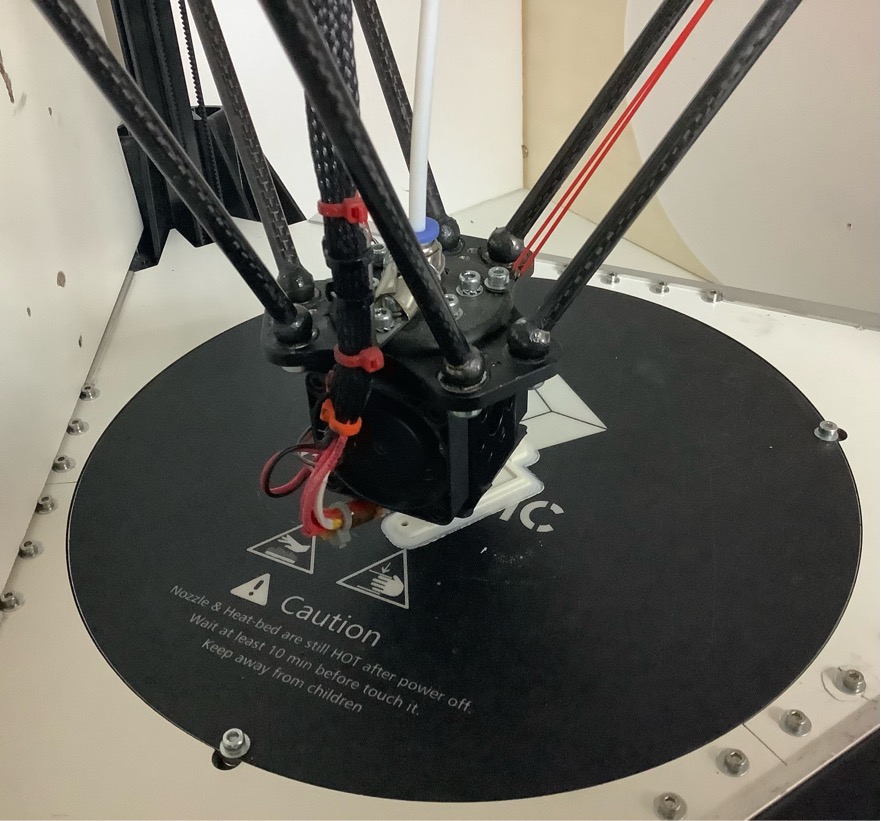

Because I rebuild the bed, it also meant doing all the lovely calibrations from scratch. Anyways, we are back to printing, and at this moment the blinking lights are blinking as they should.

So now I can print a few brackets and bits to finalize the upgrade. Another job done, and hopefully lots of happy ABS parts to come.

Still need to add the camera again, and some interior lights, and a door to keep all the precious heat inside the box, but we’re getting there!