For the first time in months it’s raining today! Just checked my rain tanks, they are filling slooow, the plumbing is ok, no leaks. (Trust me to install rainwater capture tanks, and then it does not rain for months!)

Challenge of the day: I really, really want to make these small metal parts myself. Problem I have is not Knowing Enough about milling speeds. (Not knowing anything about cutting metal is probably closer to the truth).

So when I tried to cut some stainless steel I get a red hot milling bit, with sparks flying everywhere. That, my friend, is NOT GOOD. I already went down to the lowest speed my spindle runs (10k), slowest feed (30mm/min) lowest plunge depth (0.5mm). I have a 2 mm 3 flute bit in my Kress 800.

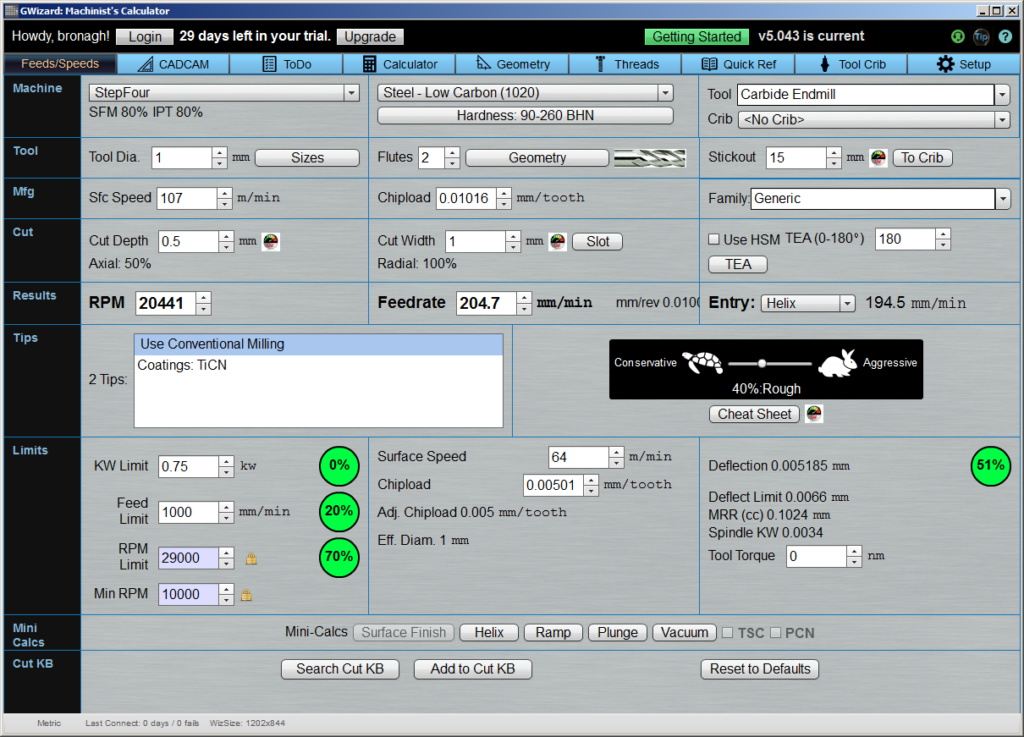

What now? I know about cnccookbook.com, but the GWizard software only runs on a Windowz system. ;-(

Anyway, installed a trial version of GWizard on the work-laptop (which I will not use for work anyway) and plugged in the numbers I used. Well, lets say it recommended I do not try this at home!

What should I do next? Get better and more suitable mills is the obvious answer! Stuff that works for plywood, does not make a good metal cutter. But first let’s see what I have. I have a bunch of short 1 mm cutters. Long story short, I need a higher feed-rate and lower RPM. Easy said. Now try to make that router behave. Since it’s raining, some good Irish country music playing in the back, lets tackle it!

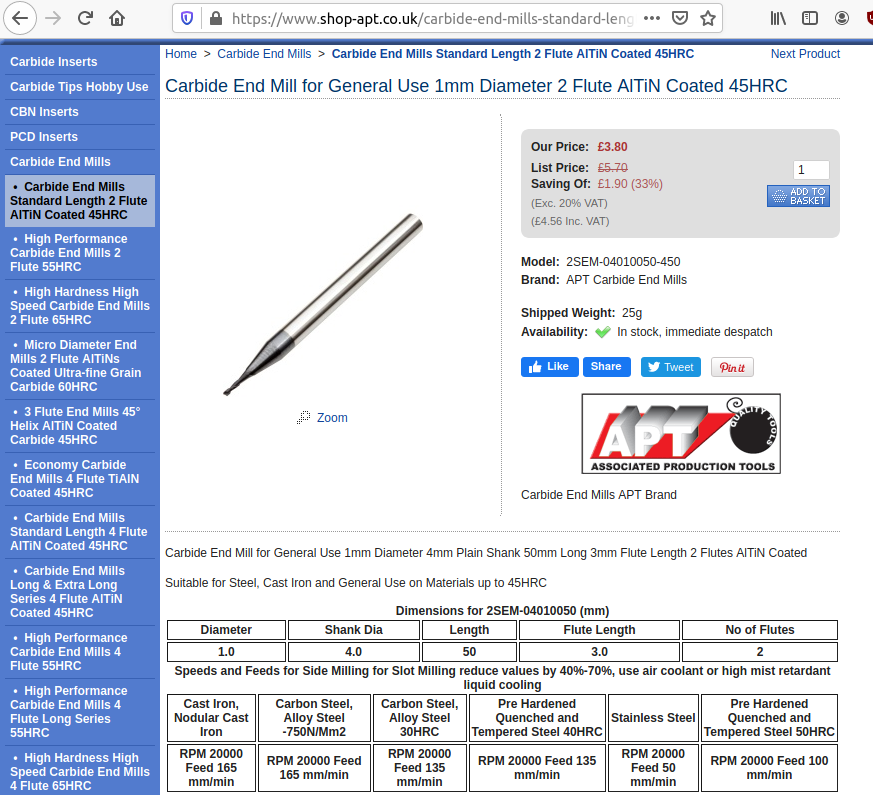

After some googlings I think I found bits similar to what I have. The company that mine came from 10 years ago, does not have a search function on their website. Going through loads of pdf books is a bit too much fun today.

First we needs something to actually measure spindle RPM. I am sure I have an prop-rpm gadget somewhere. But ‘Somewhere‘ is a bit elusive at present, I’ll try to remember where I put it. Can’t find it….

Playing around a bit more, I can actually use the 2 mm HSS mill that I have mounted now, needs 60 mm/min @ 5300 RPM, cutting depth is 0.5mm, slot width =2 mm

I did find some of my old reflective sensors, so we are almost done. (famous last words). Fire up the soldering iron, and cook up some code.