Category: Carden

-

Bike trailer test

Might as well celebrate Kings-day my-way 😉 This is the first trial fit for my new bike trailer. I still need to do something on the rear so that there is less change of anything hitting the nose or prop. Wings fit too, and even I can squeeze on the bike. All in all happy…

-

Silence it be..

A long time ago I started to silence the Carden, and today I managed to obtain some very good numbers. The weather was nice, the wind was calm, and I was off for the day. So, all ingredients were present to make it all happen. At the club we have built a heavy support on…

-

Noise (again)

I found myself volunteering for a role in the Noisy-committee of the club. We have to abide by the rules, so the first question is ”what are the rules?” Following is just a collection of bits and pieces, just to get started. DMFV (pdf LuftVO) DAEC Bocholt RC-Network More RC-Network Laermmessung1a Excel sheet for calcs (download to…

-

Sounds of silence

Finally got a 3 blade prop, because of availability I selected an Elster 26*12. Thanks to the nice sunny weather I was able to do some empty field noise tests. The plane was placed at the center of the field. The air temp was 30C, wind between 2 and 4 m/s. Humidity around 80%. I performed…

-

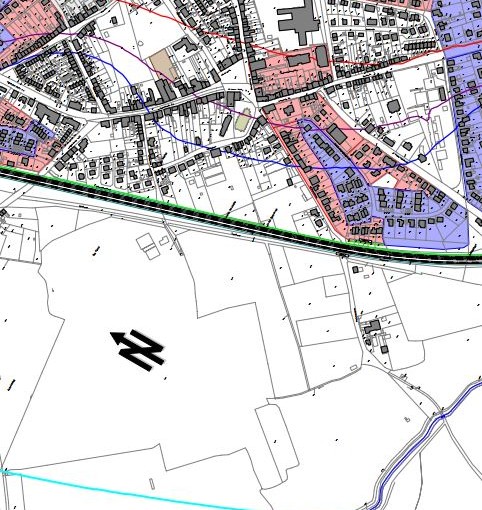

Fun at the Neighbours.

Our neighbouring club held it´s annual fly-in the other day. It´s a really laid back day where every one does what he likes to do, which is mostly fly.. I took the opportunity to bring along my Carden, just to get it used to ´foreign lands´. The club is really only a few miles away,…