..many times you have to make parts before the other parts that need to go on before the parts that you need to fit to get the job done. This was one of them. Needed to make more hinges. Not difficult, just fiddly, and a bit dodgy, since I try to cut them on the lathe, with a dodgy china cutting wheel going full speed. However, hats of to the china-folk, I have not had a single one fail on me. So far I have used approx 20 odd discs on this project.

After checking the tail, I noticed the main spar was bend. This appears to be almost inevitable when you heat bits. I decided to simply cut the middle, and add a sleeve. Problem sorted. My metal working skills don’t go so far that I can predict how much distortion I will get. Of course I could make very expensive, very heavy jigs. yup, I could..

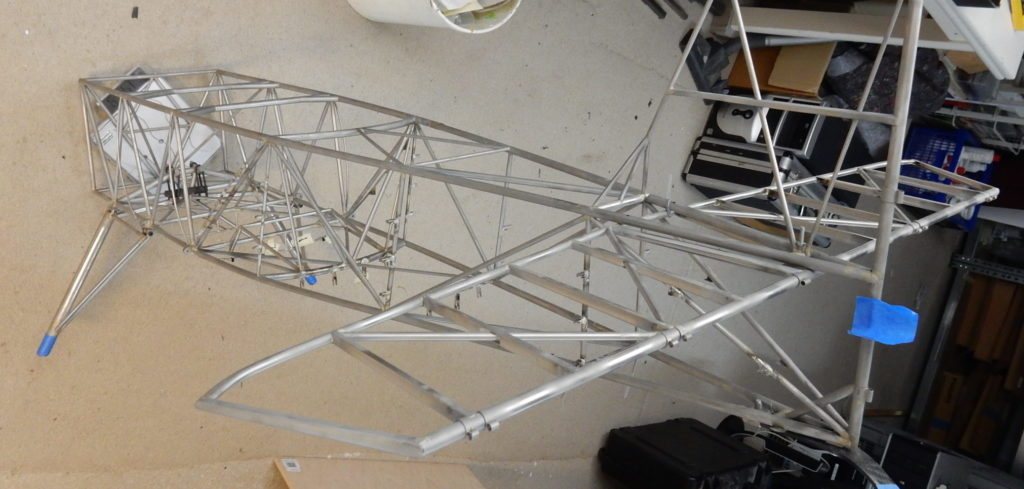

A bit of a showoff.. Starting to look like it wants to fly!

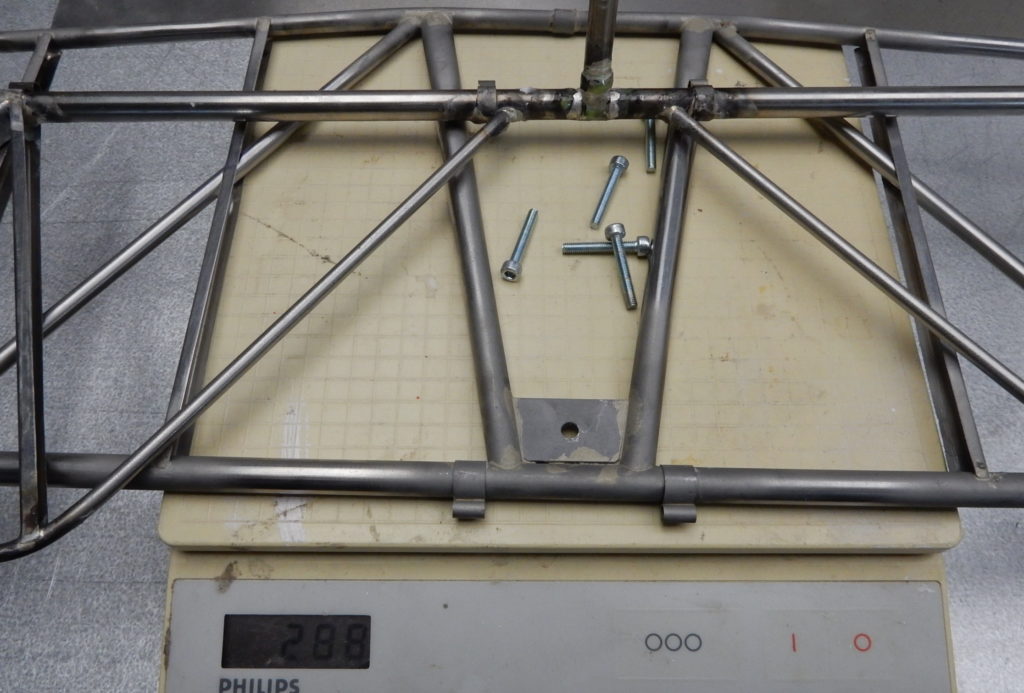

Just one more weighing session. 1569 grams as seen here. Good stuff!

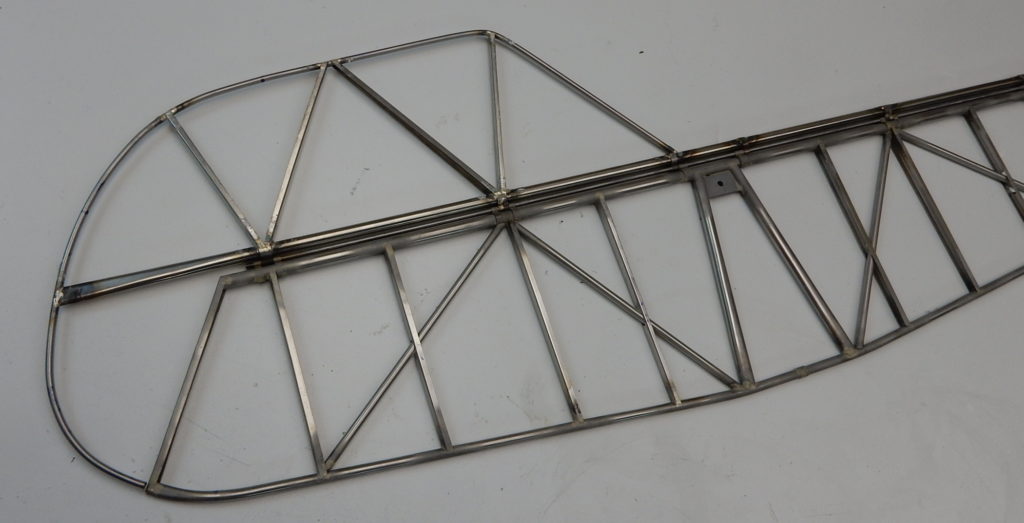

And I am calling it a day. All in all it does not seem much, but I am happy with it! The section above weighs 300 gram. As a comparison: the ”light” elevator from my 2.5 meter Extra weighs also 600 grams. Ok, there’s 2 servo’s included in that figure, but still..

Finished the rest of the elevators today, another milestone reached! Also bolted the motor back on to get a feel for the CG. At the moment I am still slightly nose-heavy, so things are good! I don’t expect to have to add any of the grey gravity stuff.

The rear stabilizer mount consists of a single bolt, as per original, the front is made up of a few gussets. I probably simplify that part. Not sure how, but simpler as original. (too many small bits that fall apart when you heat things up, is the main reason)