Category: Acroduster

-

Change of format

I’m going to make one post a week, and add all the stuff I do in this post. Unless I change me mind. I wondered how long I have been working on this: looks like first metal was cut in June 2019. Not bad. Before going too far I thought it would be a good…

-

Ailerons again

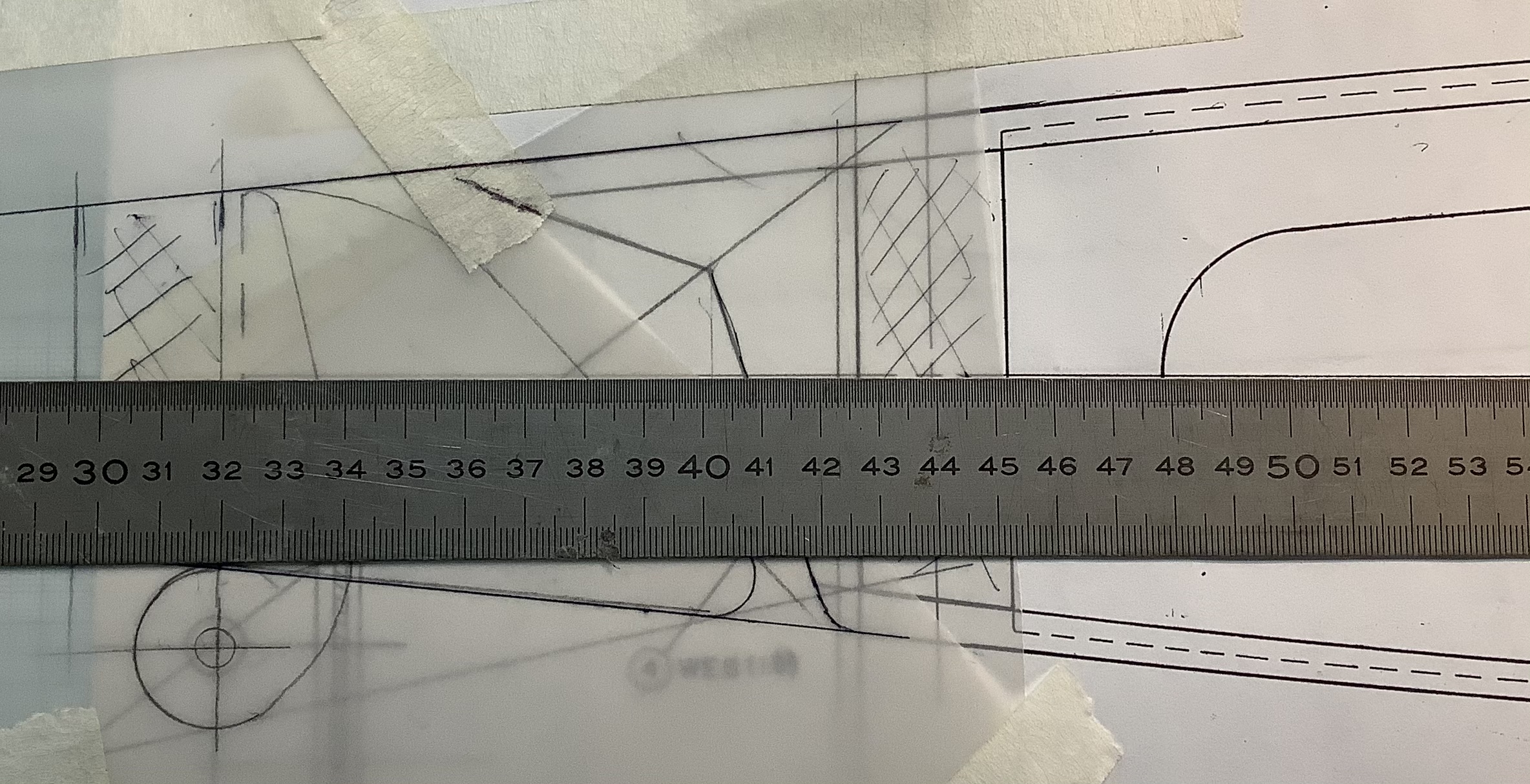

Some of the drawings are not to scale, which is no problem if you build the full size version. A few important ribs are drawn full size, and from there it is easy to find the missing dimensions. Because the dimensions on a piece of paper are very hard to determine accurately, I found I…

-

Ailerons bits

The ailerons contain quite a lot of parts. Apart from hinges, there is also a link to drive the top wing aileron. And the link to the bell-crank that is connected to the control stick. I started using a 1.5mm bit for cutting, it allows a higher spindle rpm, and better cutting of holes. Using…

-

Cutting more metal

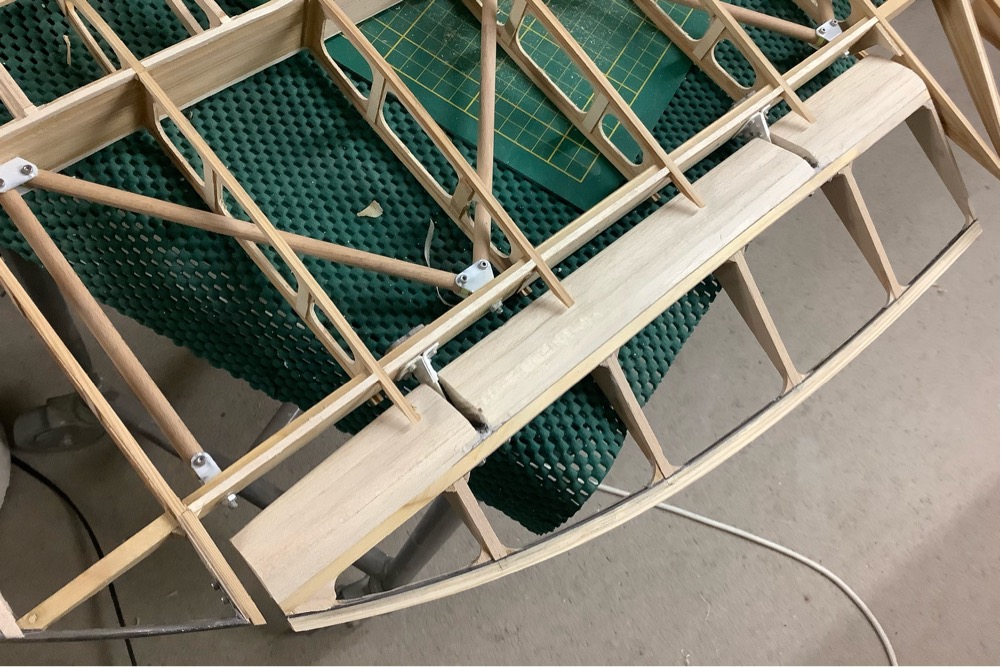

The truss tubes provide the for/aft strength of the wing. Since these are in place now, I continue with the ailerons horns and linkages. Once those are done, I can start on the aileron and trailing edge. Then only repeat 3 more times. Funny how some of the ribs look skewed, but it’s honestly the…

-

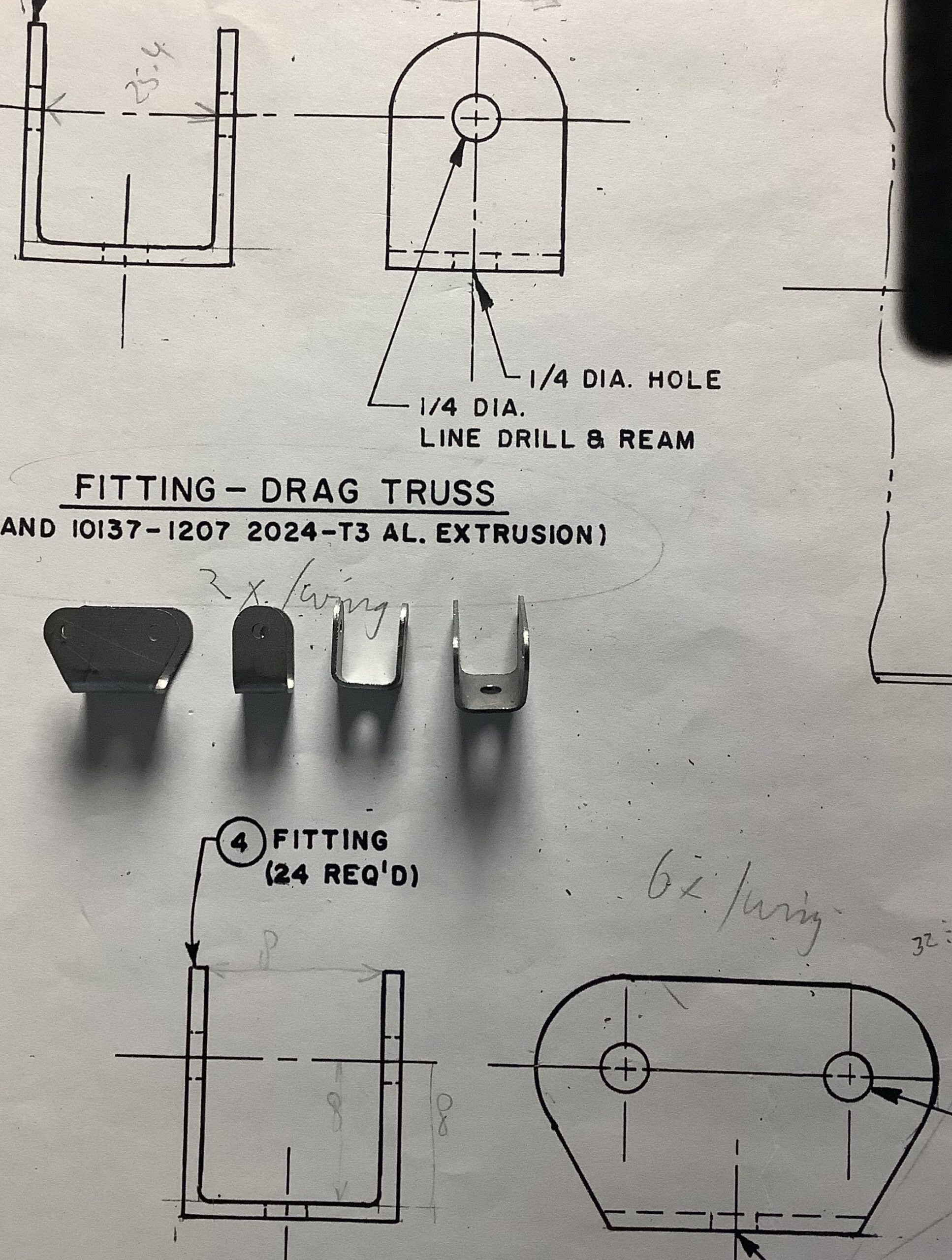

Making metal chips.

Finally getting the hang of producing chips in a consistent way. I think I need approx 36 pcs of the brackets you see in the second image. By the time I have those made, I’ll be an experd. These by the way are fittings for truss-tubes in the wings. Once the wings are covered nobody…

-

Display fun

I wanted to use this nifty little display for my RPM display of the spindle on the CNC-Router. It somehow switched to a 128*32 mode. Digging in the code, I found a problem (for me, in this sketch) Activating the 128*64 define in Adafruit_SSD1306.h library, fixed it. Yes, of course, it (they) will go into…

-

tip-work

After glueing the trailing edge wood (not shaped to final yet!) it was time to do a bit of tube-bending. It’s 4 mm tube, and for the life of me, I don’t know why it is so soft. Almost feels like copper tubing. Never mind, just try to match the shape. Trying to hold the…

-

when metal meets wood..

Making sure wing mates with the fuselage.. And a single 3.18mm pin does secure it to the fuse. Not much to say, just wanted to see how it looks. After this pic was taken, I glued in a bunch of false nose ribs.

-

there’s no way back..

The ribs trimmed to size (sort of) Even at this stage the wing is very stiff. Normally in a balsa/built up wing, it is pretty easy to twist the structure. Due to the way the ribs are built, there is an decent amount of torsional stiffness, even at this stage. Next I have to make…

-

it’s getting serious now..

A good day was had, is the saying. Over the last week or so I have been bending the cap-strips. It is a time consuming job. First you soak them for a few days, then clamp them in a jig, then let dry for at least 24 hours. Repeat. Since there are always minor variations…