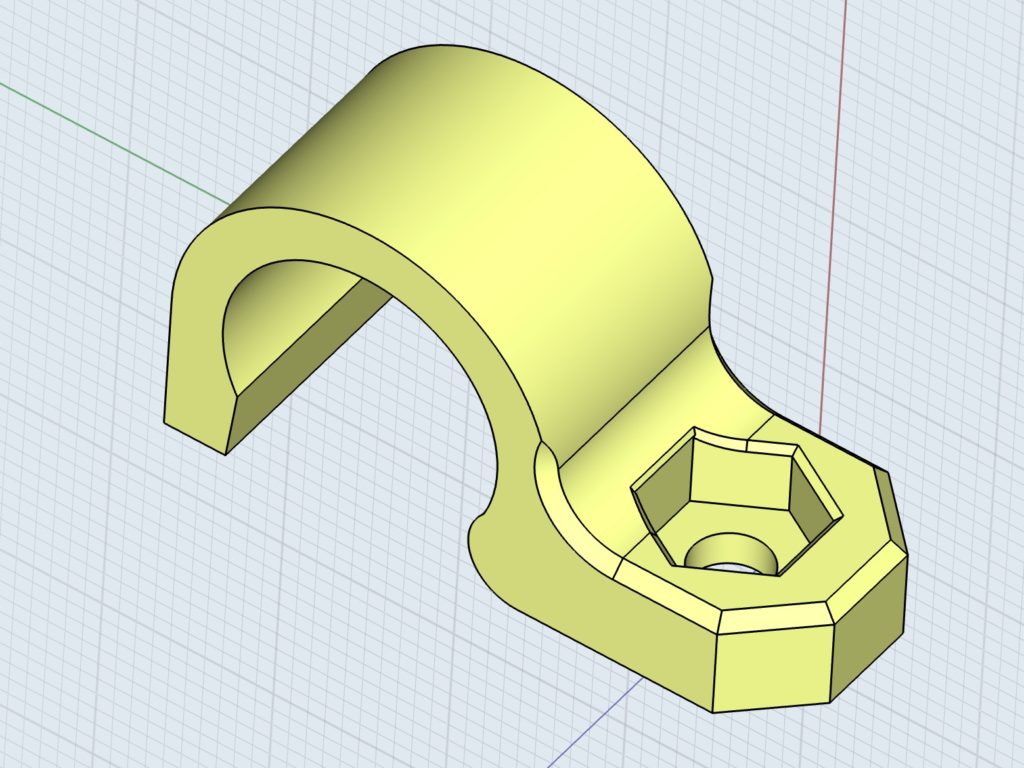

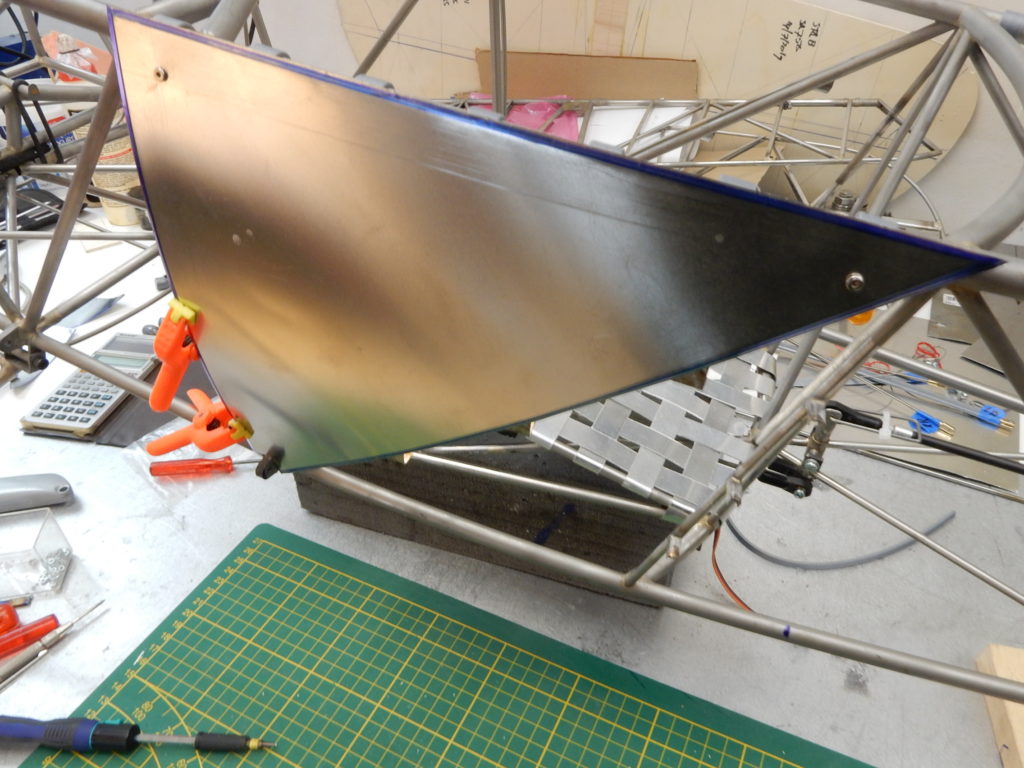

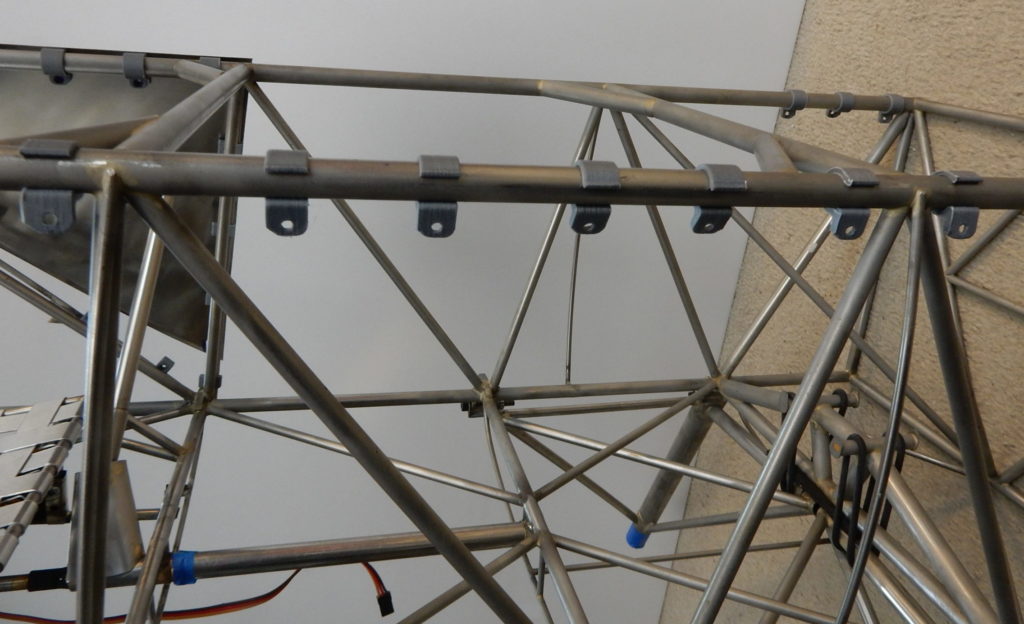

Since the winter appear to be absent in my shed, it is not too cold to make some good progress. Progress the last few days has been getting to grips with Shapr3d. I Mentioned before it is one of these bits of software that will change the way casual users are going to be designing their parts. Anyway, I need something to hold my skins on the frame. For the tails end I did not mind soldering, but preparing those bits is very time consuming. I also have it in my mind that I need to make some progress to get things flying soonish. Anyway, I figured I should try to make some clips to speeds things up.

Now that I have the hang of it, it will take me 10 mins or so to ‘design’ these parts. Since this stuff is relatively small, I do need to keep the limits of the printer in mind. Still printing in 0.1 mm layers, It takes forever, but it looks nice!

Of course the Big Question is: will this survive in real life. I guess only time will tell. There are other, more stronger filaments out there, so I am not too worried at the moment.

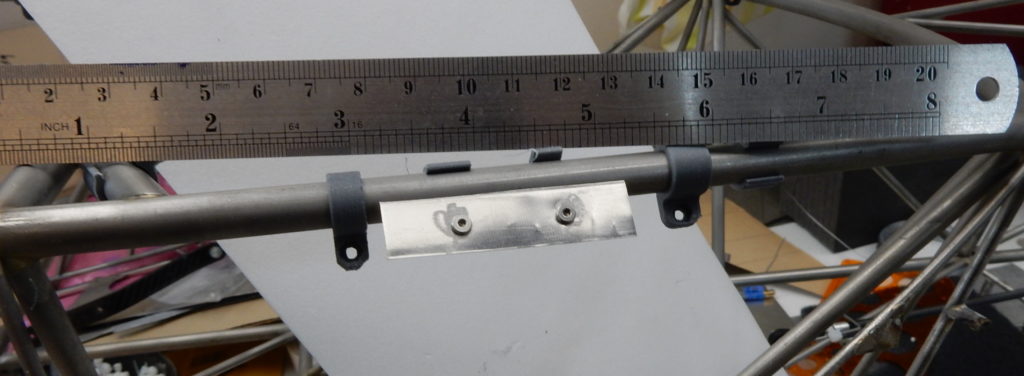

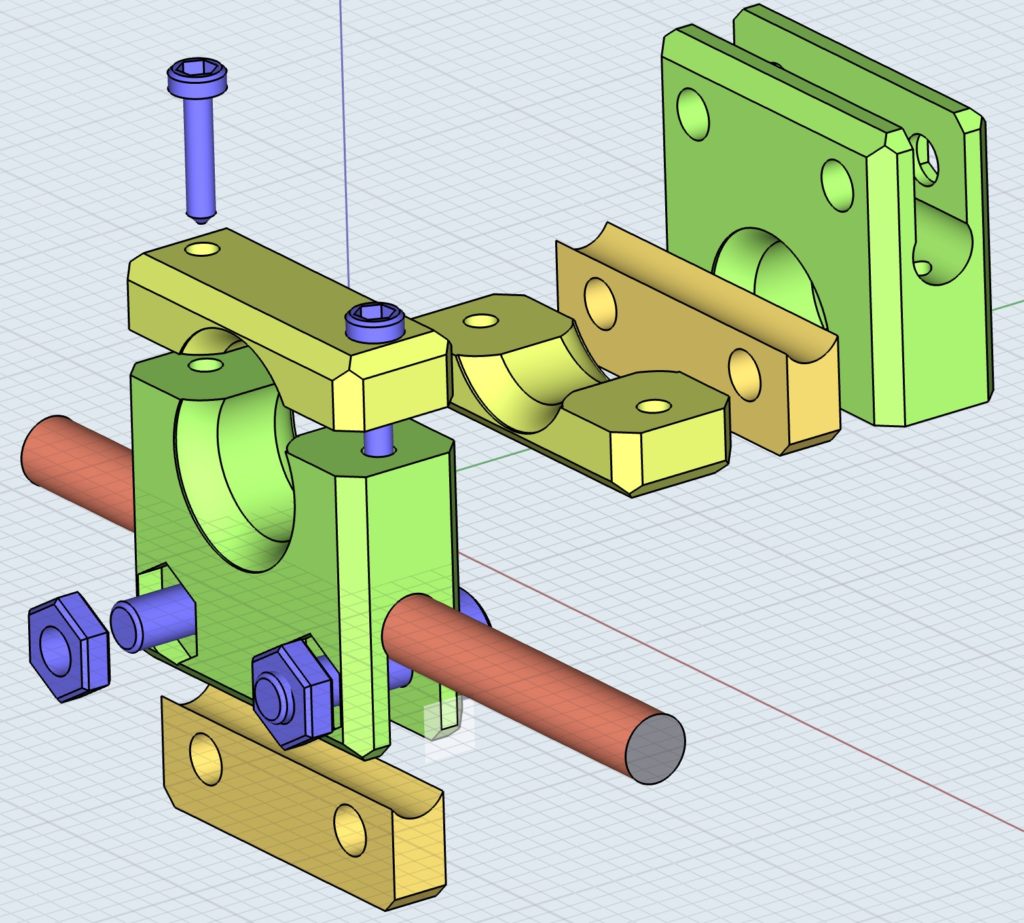

This support is for the 6 mm carbon tube. The red tube is a 3 mm cross piece to mount it on. The complete contraption consists of 3 parts. Why so difficult? I told you, it’s all practice!