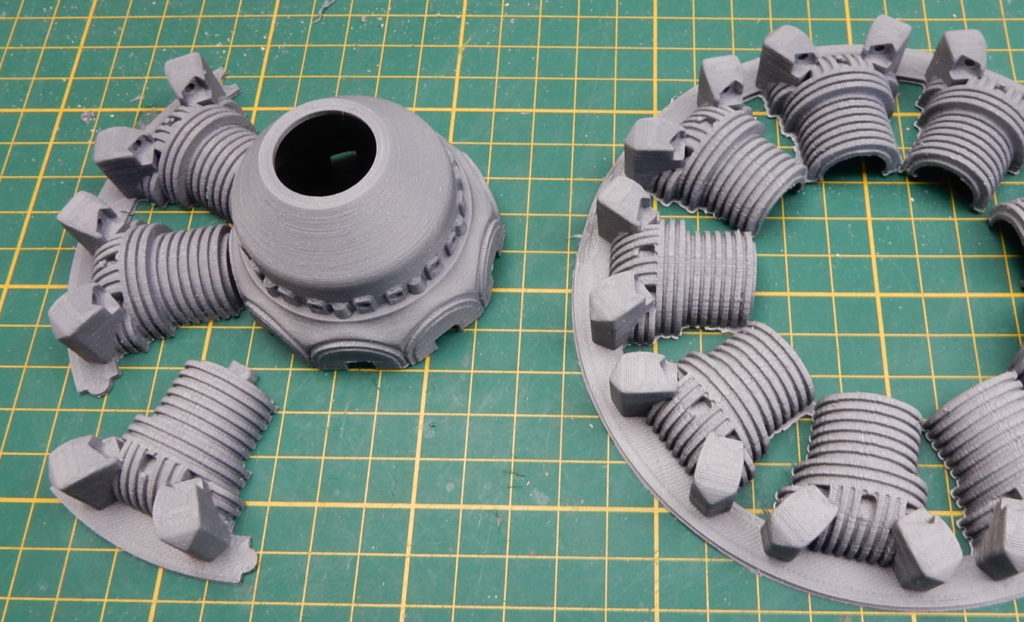

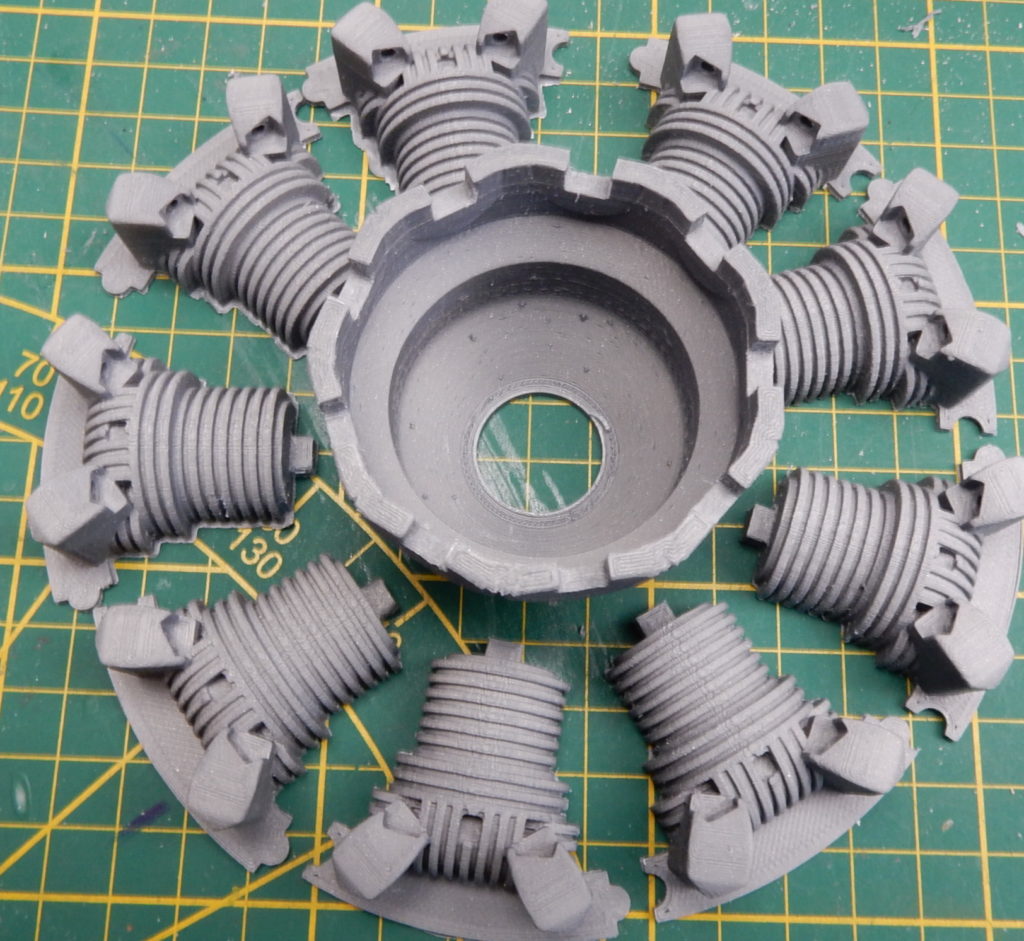

I was still not happy with my ABS printing efforts, and determined the only way forward is to chop up the large pieces. Mind you, that 9 cylinder engine is definitely a printer killer. If you can print that, you can print anything!

So, chop chop. Yep, there is an app for that. Anyways, results are improving. Also found that thinner layers do not necessarily print better. Makes sense I think, 0.1 mm layer cools down fast and prevents the plastic sticking to the previous layer. Best results are with 0.15 at the moment, and variable layer setting (in Cura), to get the top nice and smooth. Most stress appears to be in the bottom sections, even at 95 Celsius build-plate temperature, but hey, it works. Speeds are still up in the 70 mm/sec, (yup, I candothat!), because of the thin layers, prints still take many hours. (note: I don’t have enough power in the build-plate heater to reliably go over 95C. ) I can do 105C if I keep the shed warm, but not when the temp drops to 15C at night. For now, I have to live with 95C. Higher temps would relieve some of the stress, but alas, can’t have everything. As I said before, since using the magic glue potion on the build plate, I have no longer issues with parts popping loose.