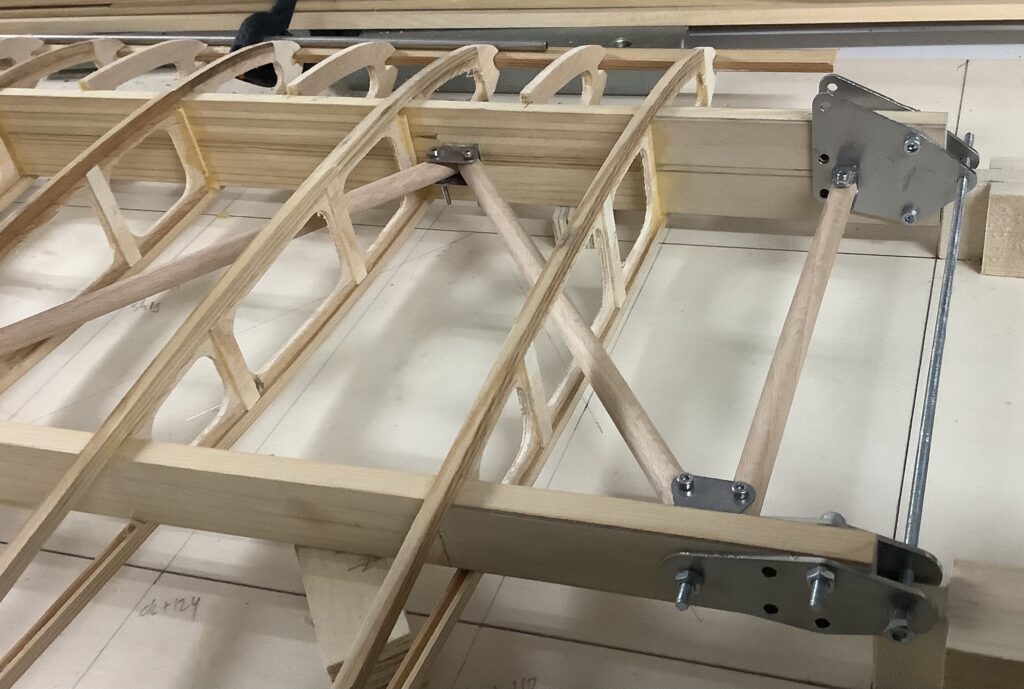

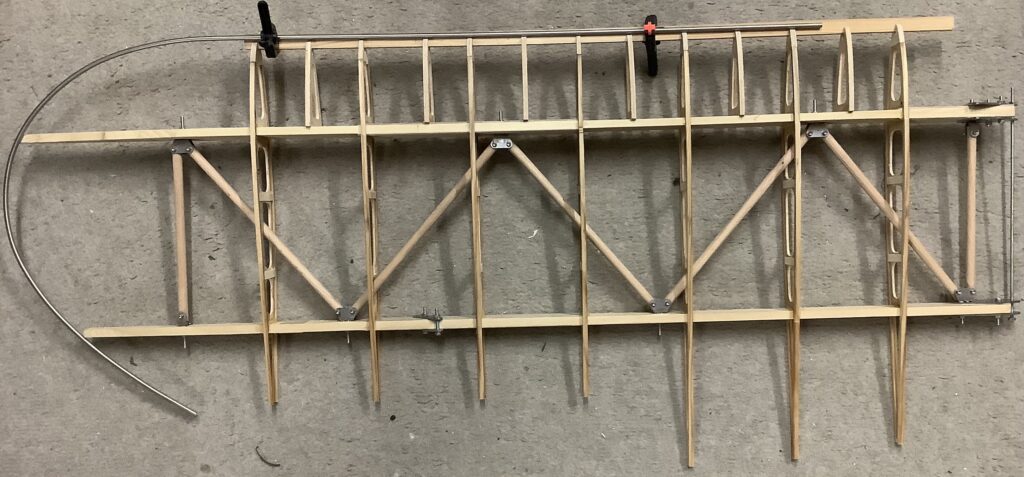

The truss tubes provide the for/aft strength of the wing. Since these are in place now, I continue with the ailerons horns and linkages. Once those are done, I can start on the aileron and trailing edge. Then only repeat 3 more times. Funny how some of the ribs look skewed, but it’s honestly the camera, real life is perfect. And that second nose rib from the left, even that is where it is supposed to be!

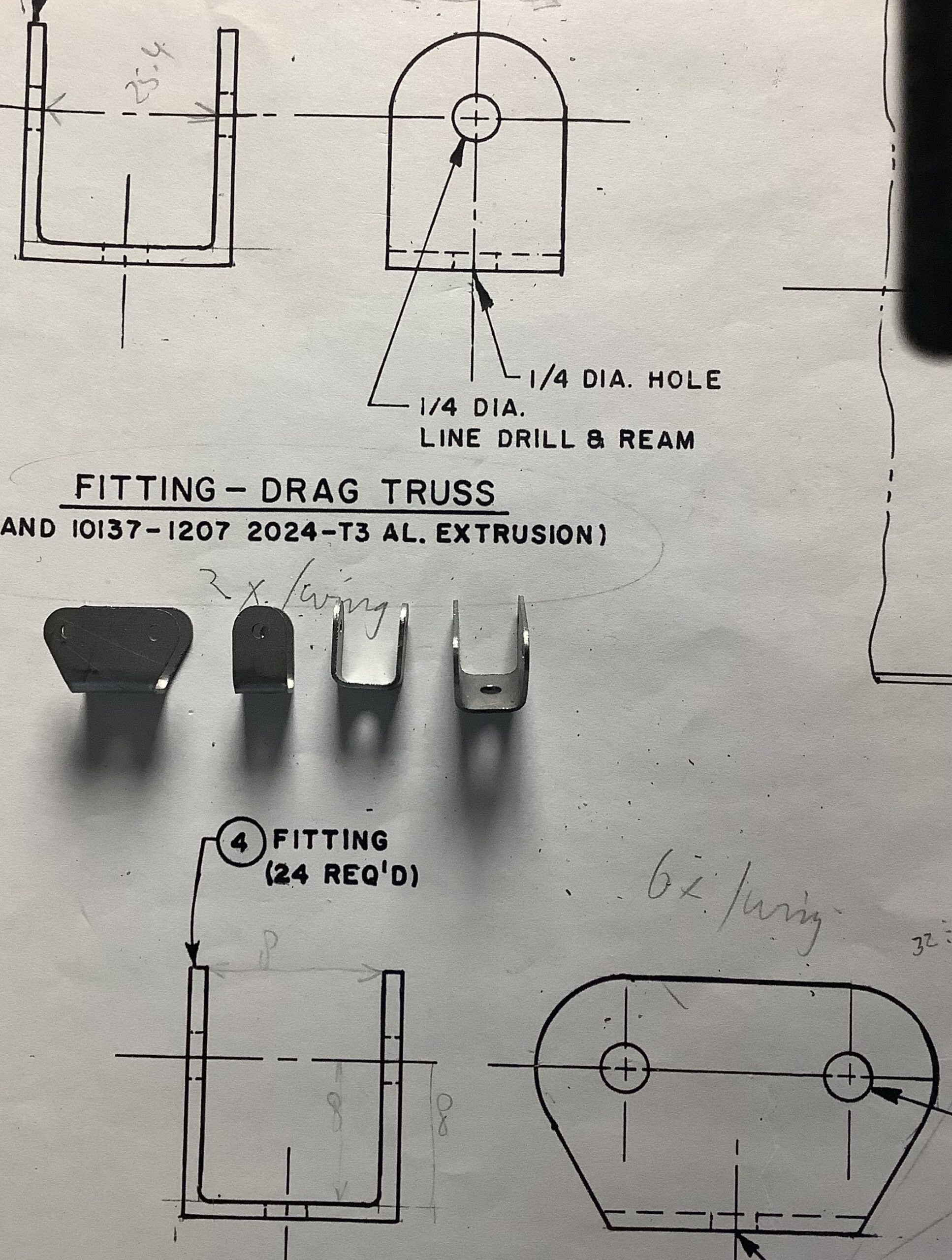

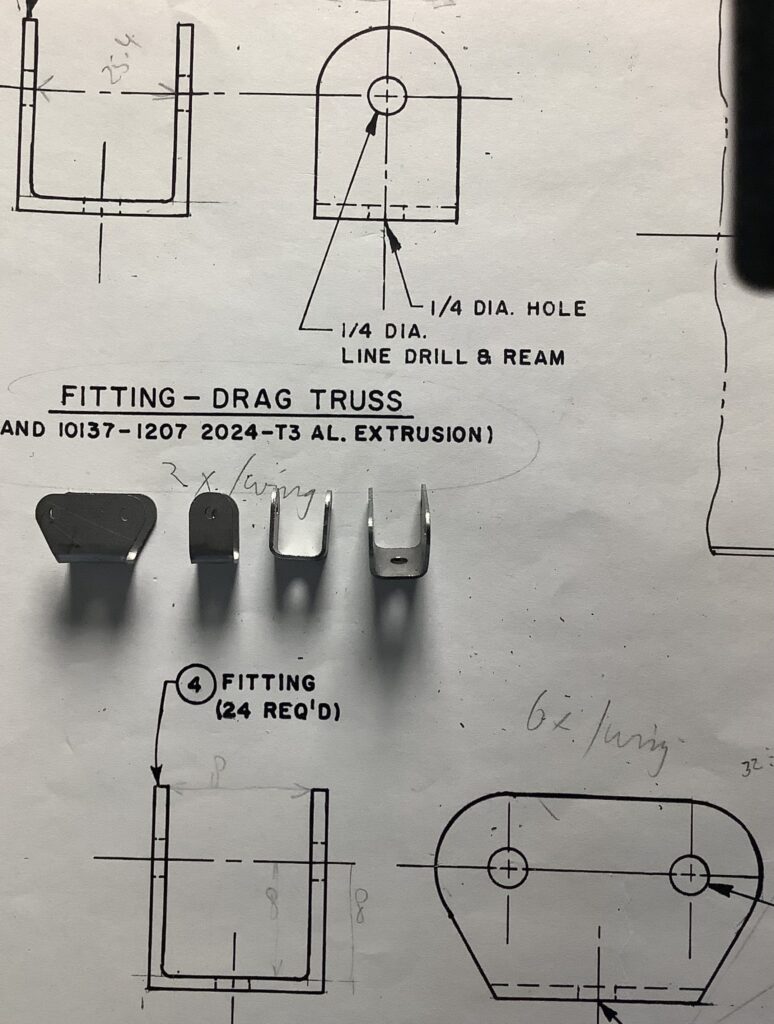

Making the aileron attachment points is next. Real life and drawing do not always match, but it’s close. (The base of the horn is approx 1 mm too high. Of course I should have measured that beforehand.) There will be a brass bushing in the big hole, and I will have a look if I can find 2 mm rivets. If not, the 2 mm bolts will do. Might put a bit of solder on the back, so that even when the rivets do nothing, it will still be stronger than needed. And I need to work out a clamp to allow accurate bending of that flange.