Tag: 3d-print

-

Oi, it’s too heavy!

Yeah, sort of expected that to happen 😉 With the added mudguard and wheel bearings and other small bits, the Hitec 645MG is struggling to get the gear up. There is a point halfway between up and down, where max force is needed, it’s just how the design of the gear works. In theory I…

-

Christmas is near, so we slow down a bit.

This time of year other things need my attention, so I’m a bit slow at the moment. I’m still working on the tail side plating near the stabilizer of the SA750. However, something as mundane as ‘a bit of plain 2mm iron strip’ proves hard to come by at the moment. Everywhere I look I…

-

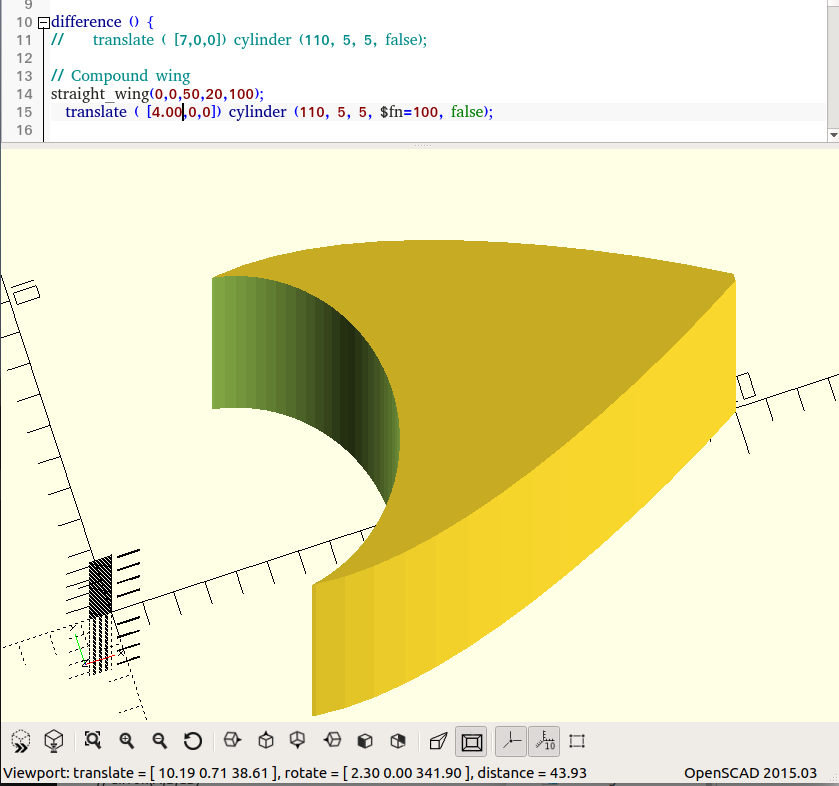

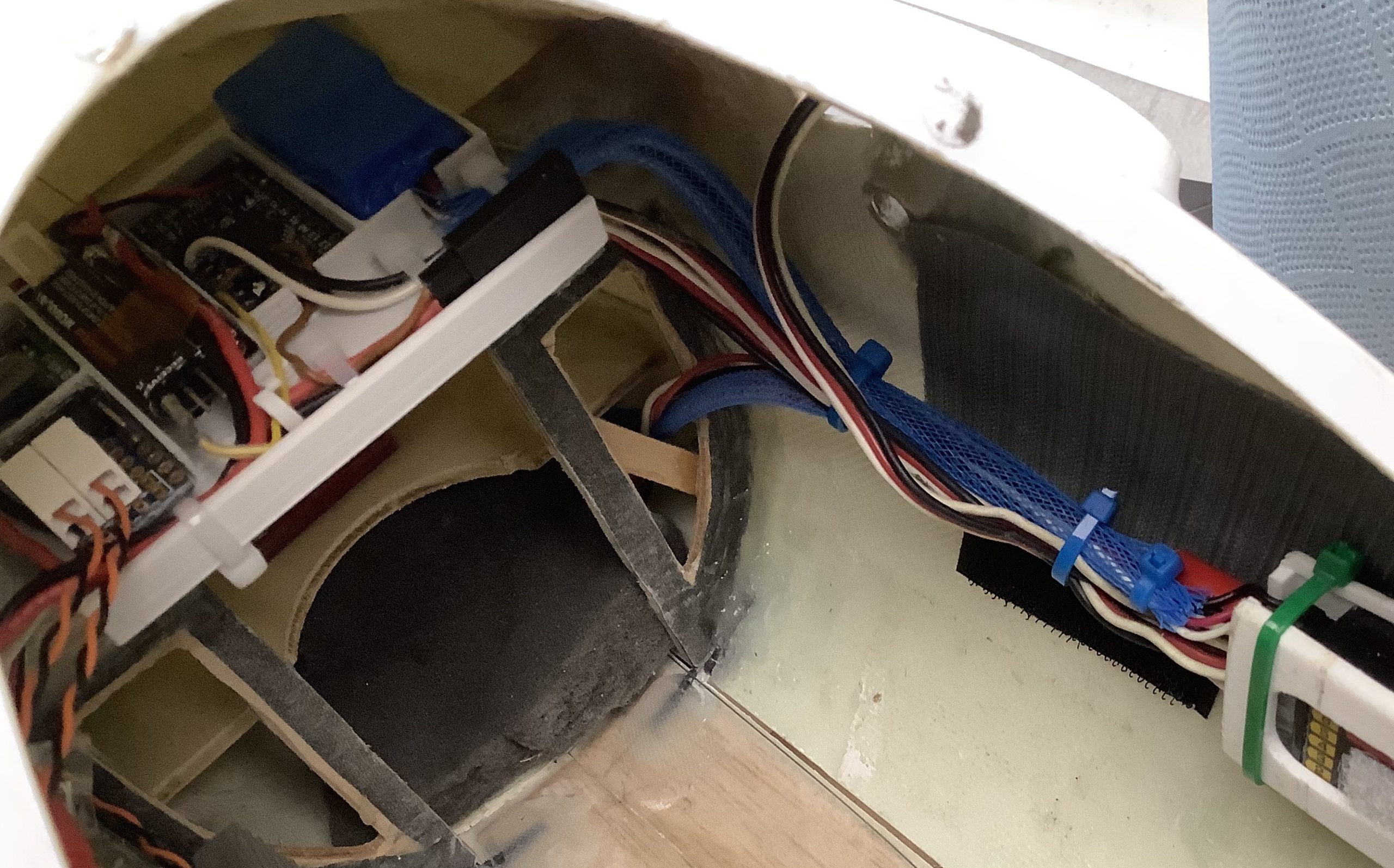

Printing some streamlining bits..

Given that it is difficult to find the right size streamline tubing, I better go ahead an make some. With the open-scad script I found I made a handful test pieces. The idea at the moment is to attach the plastic with a layer or 2 of 25 gram glass cloth. That should fill the…

-

Streamline tubing

I did say undercarriage? A whole new can of worms just opened. I had hoped to be able to use a normal streamline tube as offered by various vendors. However, can’t find anything close enough to what I want. I could make my own from round tube, just like friend Achim , but that’s a…