Category: Acroduster

-

more rib testing

If in doubt do it the Paolo way 😉 . Success guaranteed! The full size cap-strips for the ribs are 1/4 x 1/4 pine. Scaled down that translates to 2.12 mm square. That is just too small for my fingers. The plywood I have (that lite-ply) is 2 mm. I have nice 2 mm mill…

-

making ribs

With the wing spars ready, it’s time to start thinking about the ribs. On these wings, nothing is straightforward, every rib looks different. (which gives it those nice wings 😉 Luckily the designer was smart enough to keep all the ribs up to the aft spar the same, so the only difference is the rear…

-

more small steps..

At some stage, after laminating the wing spars, I needed to bevel them at 4 degrees for the forward, and 6 degrees for the aft spars. Could have done it by hand, but this was quicker. (After spending 2 hours thinking about it, and trying to mount the planer. ) Only do this under adult…

-

Nothing like a good plan..

After many thinking’s and deliberations, I came to the conclusion it would be better to build the bottom wings first. The mounting points are already fixed to the fuse, so their alignment is hardwired into the frame. When the bottom wings are done, I can align the top a bit easier. I had planned on…

-

Back to building

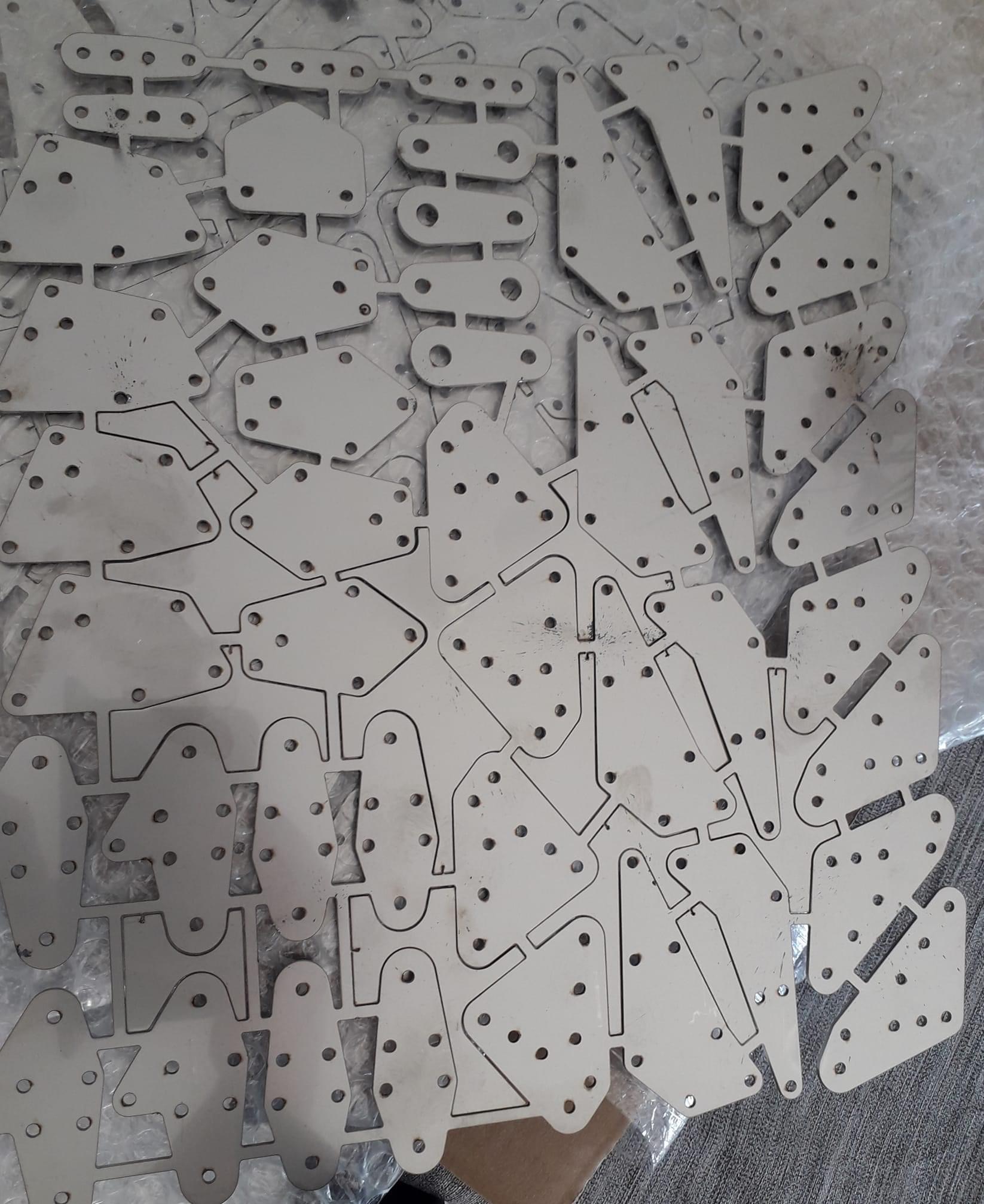

I got a nice envelope of Bling last week. The process of getting from the parts I drew to something in my hands is not that complicated. Submit a dxf file, receive a quote, say yes, wait a few days, done. And the good part is, it is not breaking the bank! The one thing…

-

Lining it all up

Getting the cabane structure built was always going to be one of the challenging bits of the build. So, off we go. With the aid of my trusty 0.01 degree level, I’ve now lined up the fuse and a flat plate that will serve as the build-reference surface. As we speak, I just finished setting…

-

TLAR (that looks about right)

That’s the way we used to (and still mostly do) design our stuff. If it looks right, it will fly right. Works since the days of the Wright brothers (and all those that went before and came after them.) However, fun has to be had! I need to sort of start thinking about the wings…

-

Parts I got somewhere..

Should make a note of where I got stuff, because I keep forgetting 😉 Those nice 2 mm flatheaded bolts: https://www.aliexpress.com/item/4000053423419.html should get you close..

-

A day figuring out the center section.

Making the top wing center-section is a bit of a challenge. The drawings are not very clear. I started by making some fake parts, and see what makes sense. There is also no need for the wing-tank, which saves a bit of hardware. Given that the original construction was usually very clever, it pays to…

-

Random stuff.

Had some issues with the 3D-printer. Sometimes it would tell me the bed was not heating at the required rate and shutdown unceremoniously. Not Good. After the usual suspects were proven to be innocent it was the ntc resistor under the bed. Tiny as it is, it is a vital bit. Why oh why it…