Author: Kees

-

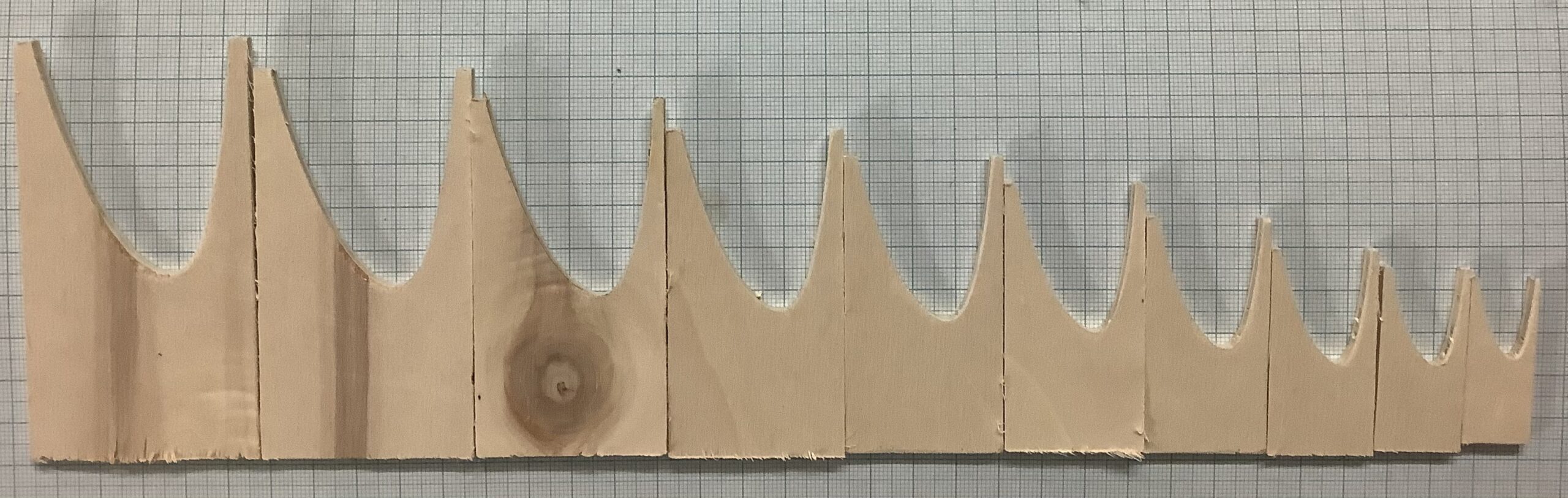

Ailerons bits

The ailerons contain quite a lot of parts. Apart from hinges, there is also a link to drive the top wing aileron. And the link to the bell-crank that is connected to the control stick. I started using a 1.5mm bit for cutting, it allows a higher spindle rpm, and better cutting of holes. Using…

-

Cutting more metal

The truss tubes provide the for/aft strength of the wing. Since these are in place now, I continue with the ailerons horns and linkages. Once those are done, I can start on the aileron and trailing edge. Then only repeat 3 more times. Funny how some of the ribs look skewed, but it’s honestly the…

-

ASK21, lets start

I’ve been looking at it for too long, so let’s get going. As always, first things first. The wings are what keeps us up there, the rest is only there to keep the pilot dry and comfy. The kit I have was produced by Heinz Maassen Flugzeugbau. (I believe Heinz passed away early 2015) ….Die…

-

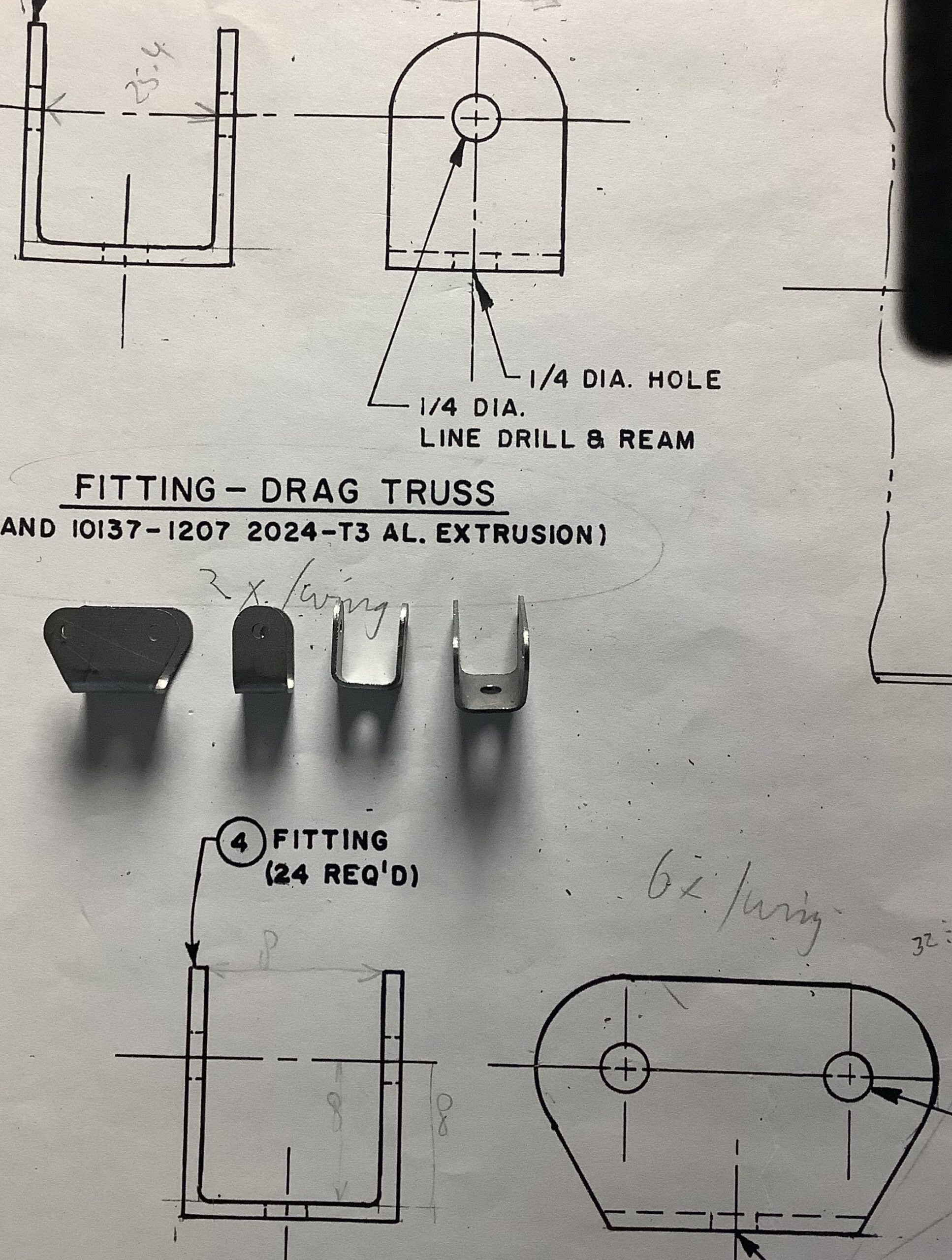

Making metal chips.

Finally getting the hang of producing chips in a consistent way. I think I need approx 36 pcs of the brackets you see in the second image. By the time I have those made, I’ll be an experd. These by the way are fittings for truss-tubes in the wings. Once the wings are covered nobody…

-

Just another relaxing day

I finally reached D-Day (Departure-Day) and have been taking it easy the last few weeks. Easy as in not spending time on modelling activities, but more time on ‘Life’ things. But, since a few days, Autumn seems to have arrived, so a good time to warm-up the soldering iron to keep the man-cave warm. One…

-

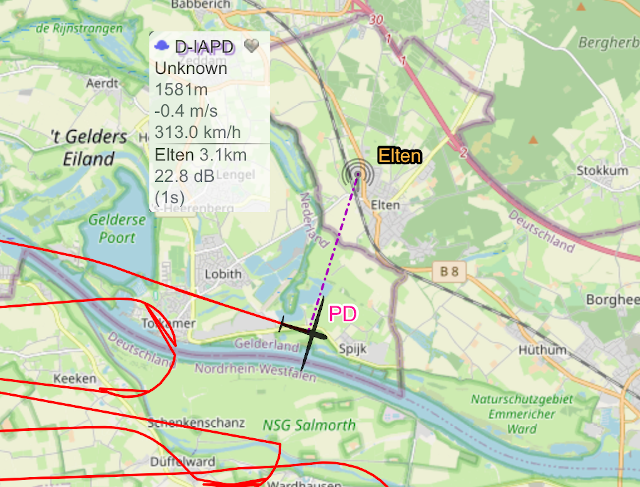

Flarm tracker

In the summer of 2020 I had the idea that I wanted to let full size pilots know where we are flying. There is no easy way to do that. But then I found the Open glider Network. What started out as a ‘just for fun’ project, turned into something that I don’t want to…

-

The first cut is the hardest

What took you so long? No idea.. More then 10 years ago I got myself a CNC-router with the idea that I would be able to metal metal parts. I’ve used it up to now mostly for non-metal parts. But retirement has given me enough time to finally sort things out. That and a better…

-

How fast we goes..

Finally got the airspeed sensors, so what better to do on a rainy afternoon them to play with them? First the specs: Datasheet, and a picture. Bear in mind that all these diy chips are basically old stuff. This one dates from 2012. Obviously nothing wrong with them, they are still used in a lot…

-

today’s harvest done

This series has an extra voltage regulator, I have a feeling the version that runs straight on the 5V from the receiver is a bit too sensitive to voltage fluctuations. These ones are to be fed from a 2S Lipo or LiFe supply. Time will tell if I am right ;-

-

1012 mBar in the shed.

Continuing with the Barometric Pressure Sensor saga. Here are the data sheets for the MS5611, and the MS5607. The parts that show the different methods for calculating pressure and temperature are highlighted in the images. Use the linked datasheets if you can’t read the fine print. Crudely changing the code at least gives me good…