What did you do THIS time? A friend slightly bent a Slope Infusion. I volunteered to fix it. Nothing dramatic, but before you know it turns out that the 5 minute job, runs into a day’s work.

I won’t bore you with the details, but I needed to repair the fixing bits for the outer wings. Model is produced by ‘Ralf Grüner -CNC-Service’. It uses a very simple, clever method to secure the outer wing sections. Essential parts are a screw and a clip that gets inserted into recess, so that it locks the screwhead. During an enthusiastic arrival, the clips held, but the ribs into which they are glued did not. To repair the damage I had to remove the plastic parts that are essential in the operation, before I could glue the ribs again. This of course is a one way operation, resulting in ‘oops, now what’. Well, looks simple enough, let’s just print a few spare ones. Can’t be that difficult. And indeed, designing a fresh set was really not that difficult, printing however turned out to be a different story. For reasons only known to the Printergods, my printer packed up. It tried to start a print approximately 5 mm below the bed. This, I am sure the reader will understand, is Not Good. The usual routine of ‘let’s turn it off and try again’ was a recipe for the next disaster. Maybe I should try to understand why it does what it does before trying again. So, after a few hours trying to figure out, why something changed, I decided to scrap all my configurations and start fresh. And yes, that worked. Which goes to show, even software gets tired after a while. (That would be approx 1000+ hours printing). Do I know what went wrong? yes, somehow my bed-mesh was corrupted, and it told the printer that lower is better. No idea how it happened.

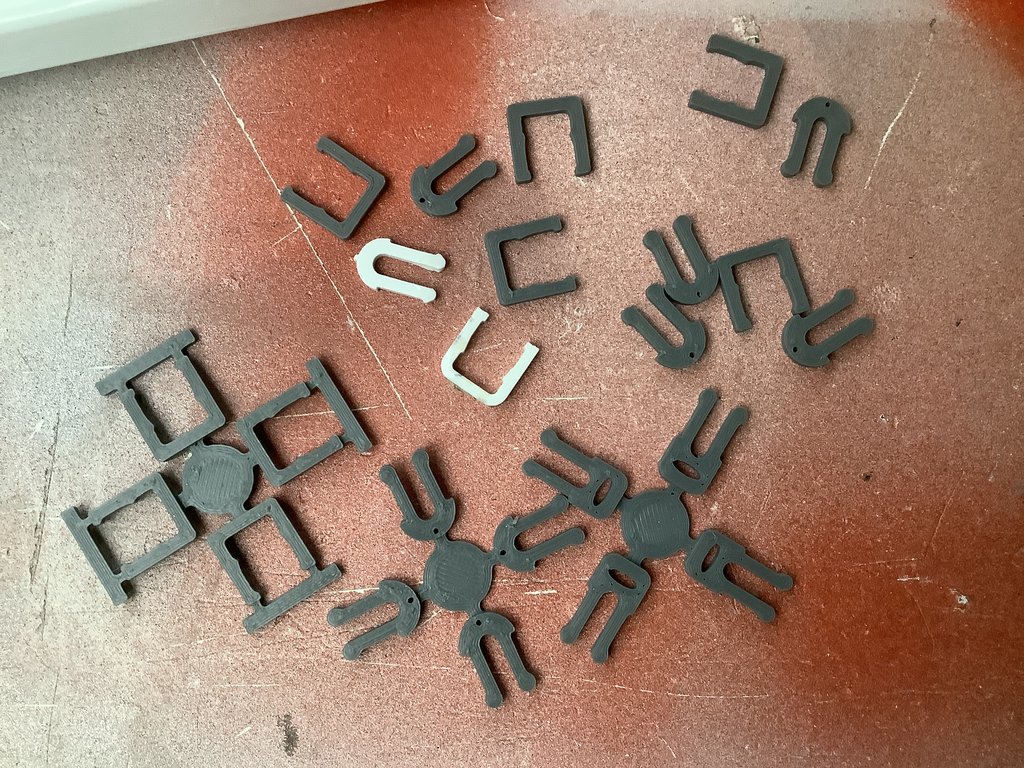

So, after the printer was printing again, I managed to print the clips, and a handful of spares. ( Life being what it is, once you have a spare, you never need it again. No spares? You will look for some!)

During my coffee break, I was looking at the website where we got those gliders. Note my surprise, when not only do these parts exist at spares, but also every other major part of the glider comes as a spare. I must say I am impressed, because this has always been the problem with wooden kits. You never can get spares if things break. So, well done Ralf Grüner, on you go!

To go back to the beginning of this ramble: I can now make these parts as well, for approximately 5 cents material, and 15 minutes looking for the file and hitting the print button. I could have ordered them for 10 euro, including a postage stamp. But there is hardly any satisfaction to be had from pushing the button to buy a part.

This way, I fixed my printer, got spares I will never need, and overall had a good day. Yes, it cost me a day’s worth of fiddling, but that is what retired engineers do. Oh, it’s raining all day, so not going outside to take a picture of the refinished Slope Infusion.