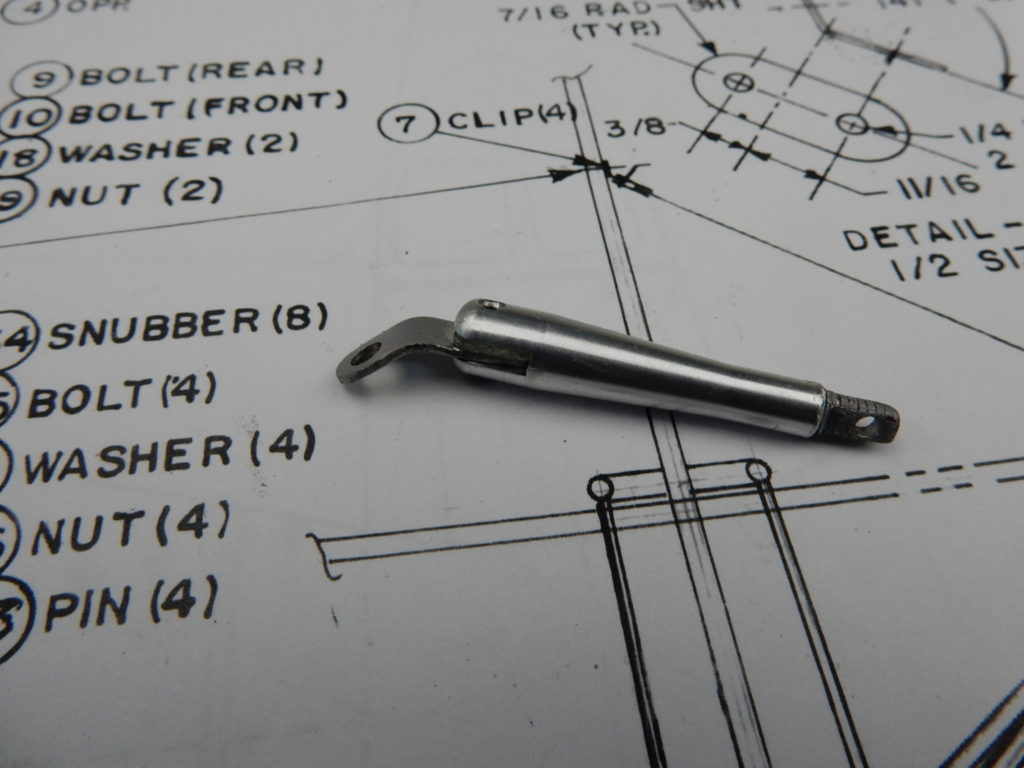

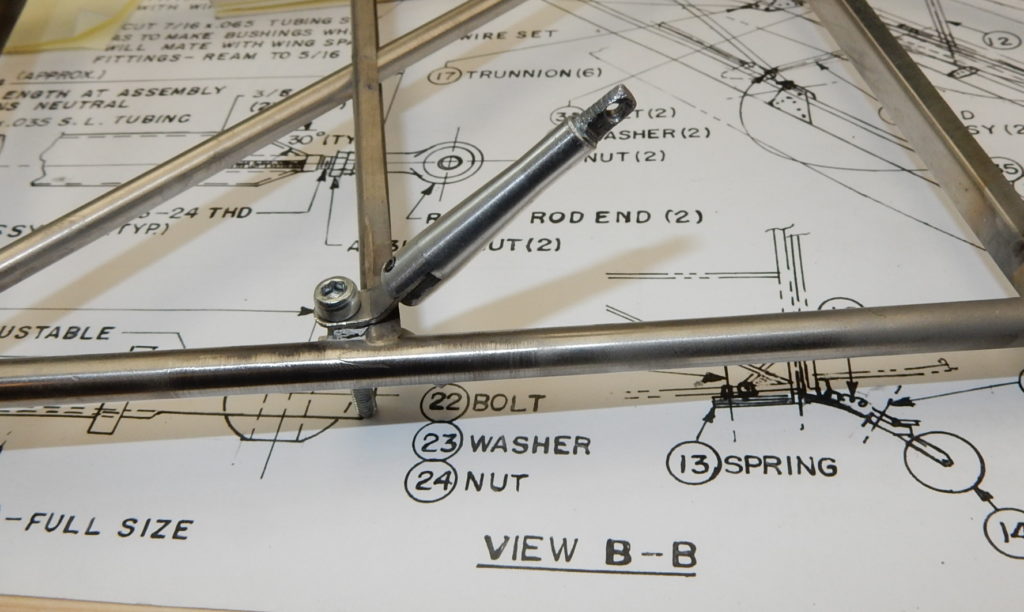

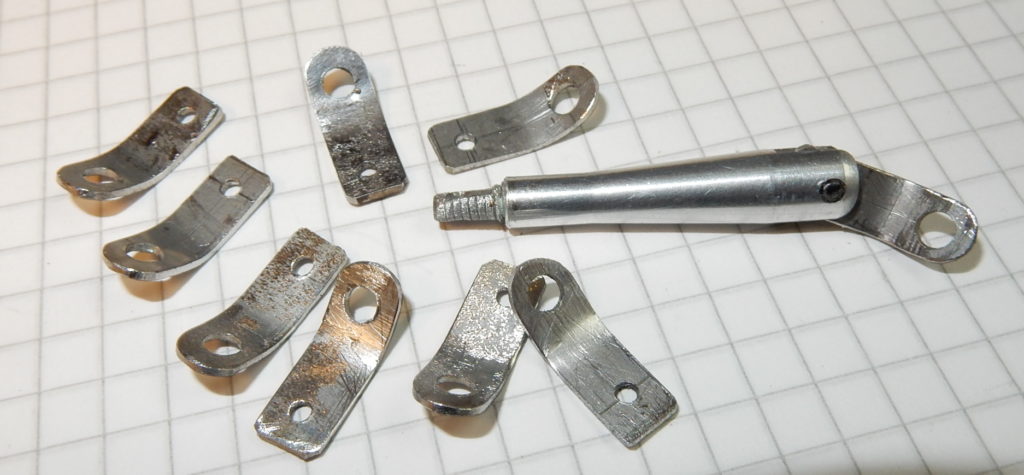

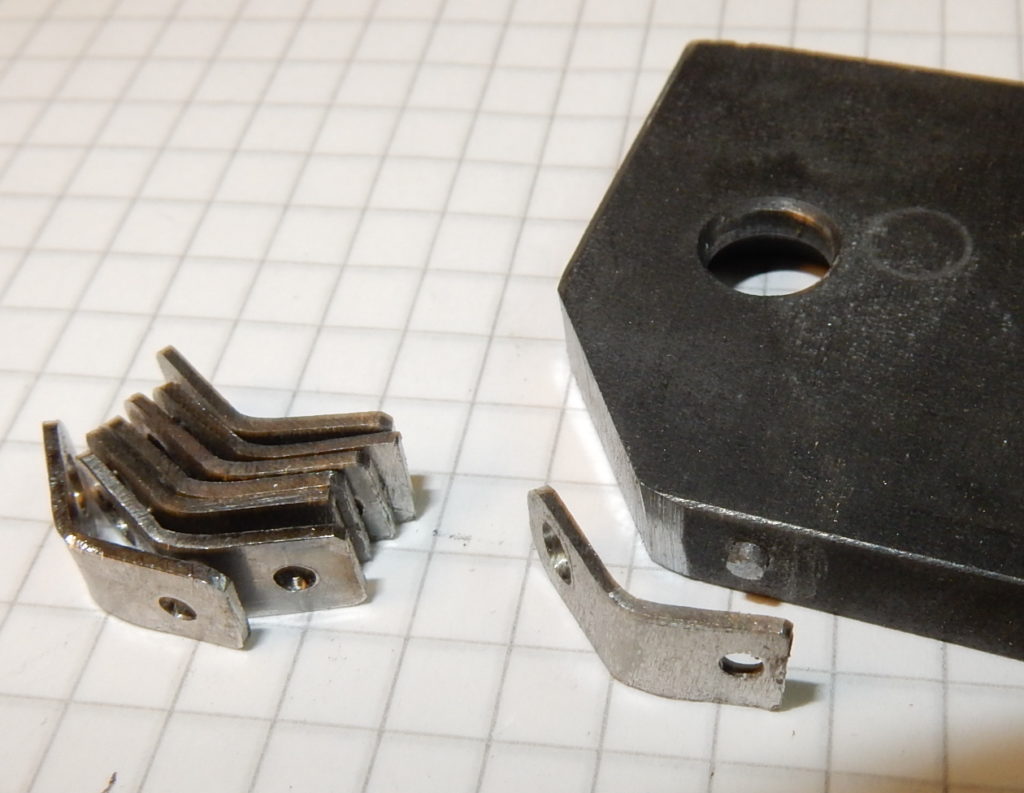

There must be a law for that! Anyway, at the moment of writing I have half the brackets done. Most challenging part is cutting without cutting meat-ware. So far all fingers are present. Material is 0.8 mm stainless, not the easiest to work with. I had some nice clevises from Pete Tindal*, they look good and do the job just fine. They were meant to be used with glue and a 3 mm carbon rod, but cutting a 4mm thread in the hole works great. Cutting a 4 mm bolt to size and drilling a hole for the wire seems to work. I might tidy up the bolt end, it does not look to grand. ( *only people of a certain age will know Pete)