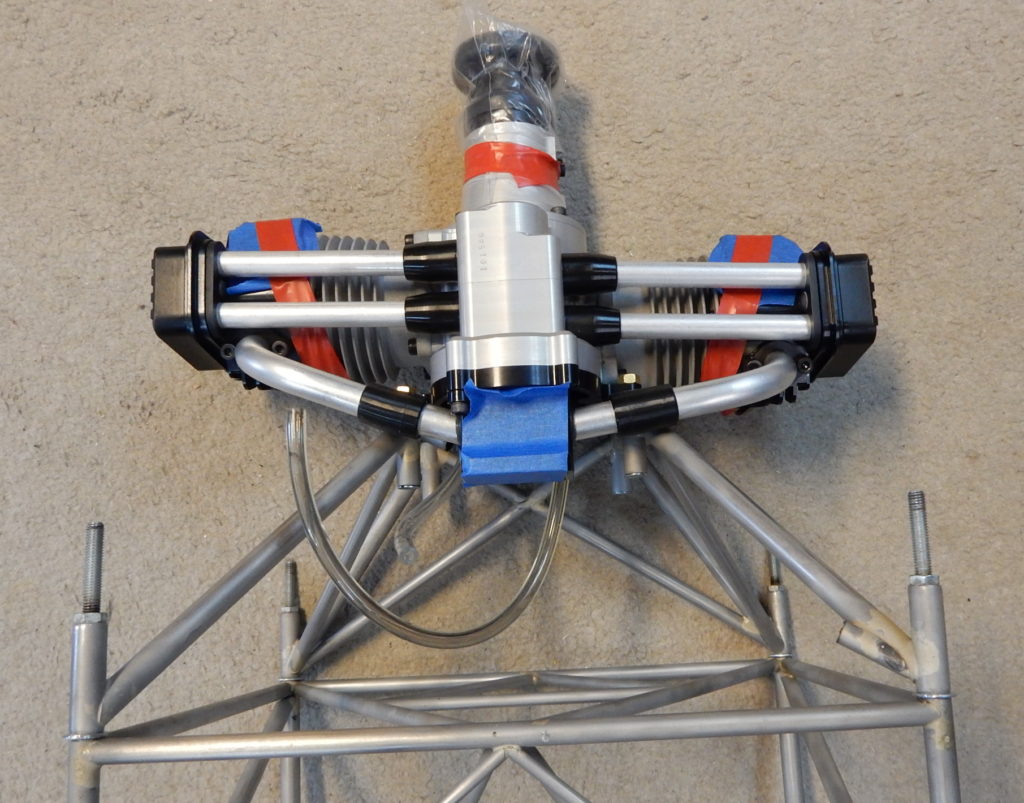

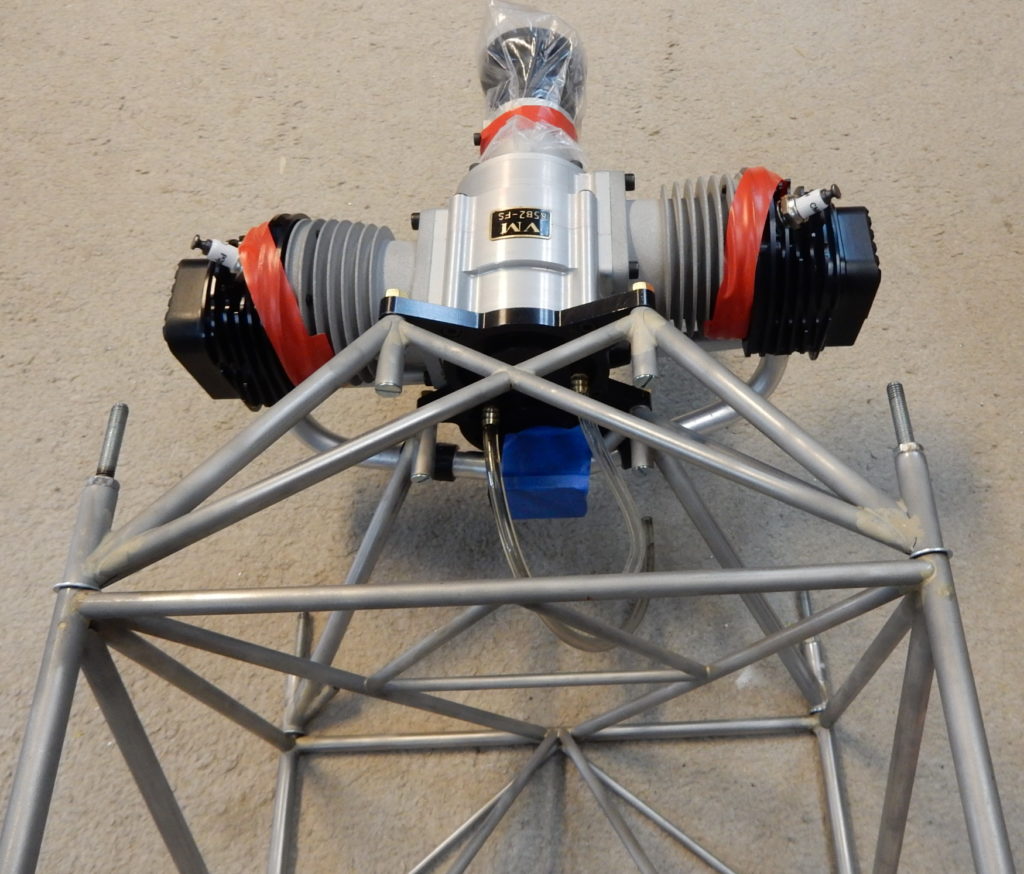

Once it is all finished it looks easy. At the start it’s more like ‘how am I going to tackle this? I decided to use a 3 mm alu plate as a mount for the short tubes that hold everything together. This way I could mount some 5 mm wire studs to hold the motor, and line things up as I think they should be. The frame bolts are actually mounted in the frame, which makes everything line up perfectly. Mind you, this is probably version 1, when I get further along I might need to change things because of balancing, place for the exhaust, servo’s etc. The mounting tubes are still oversized, but better a bit longer then too short. The top cross bracing went OK, when I started adding the bottom ones, I found there is no space for them because of the Walbro carb. In theory the supports on 3 sides would be enough. I also have to think of a place for the exhaust, might have to make something special, since I really don’t want the hot exhaust next to the carb.

I ran out of tubes, so next stop is to figure out what I need, place the order and wait.

The mount weighs nothing of course, I did not weigh it, but I would guess around 90 grams.

For the clever ones: no sidetrust in the mount? Based on good advice I decide to use a throttle to rudder mix to keep things lined up. I can always change it! I also might use this mount for running in. (There is no need for it, I know, but I want to see how it holds mechanically before letting go into the big blue yonder.!)