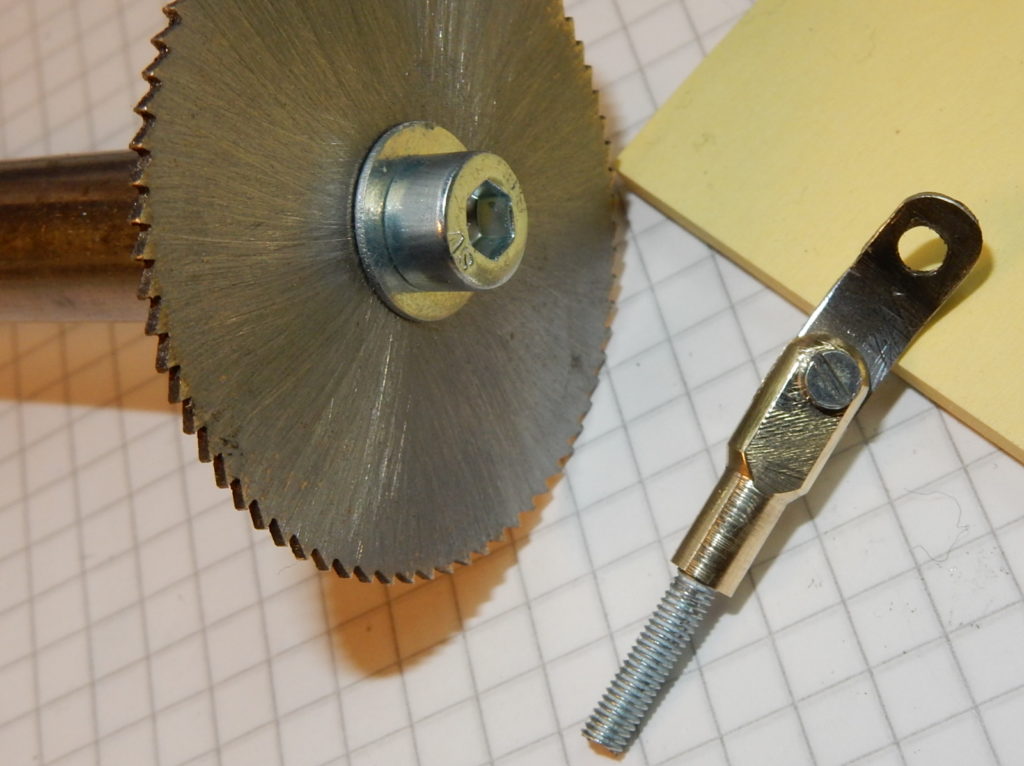

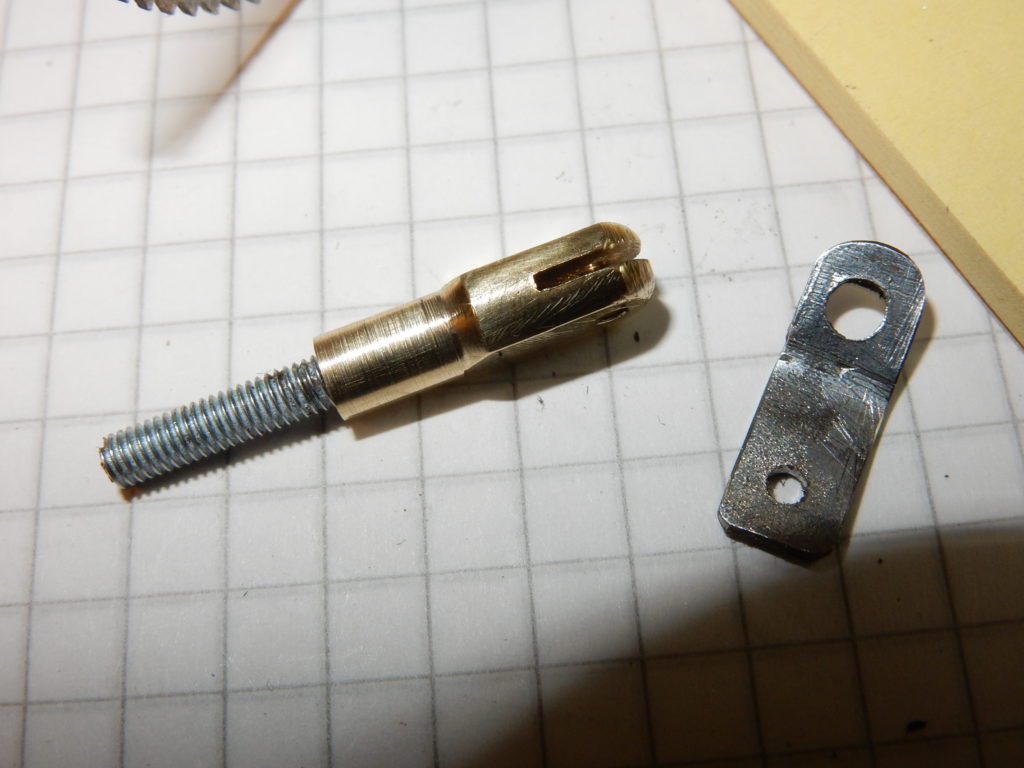

..so fiddling around I managed to make a better one, that looks more scale like. I did have some thin saws from the pound shop so here we goes. Those things are undoubtedly not made for what I use them for, but as always, go slow and be careful. I tapped a hole in a 12mm rod I had lying about, and fitted the blade. Clamp a 6 mm brass rod in the support and go slowly. The design is basically copied from Dubro 4-40 rod ends. I have a few of those, but they are tapped for 4-40 thread, with is approx 2.8 mm. Not enough flesh on them to tap a M3 hole, and I don’t have any imperial taps/dies lying around to make the rods. Hence the ‘need’ for DIY.

Next step is make a handful more, and get the streamline tubing for the bottom braces. Stab side of the tube will be flattened with a hole drilled through (easy), the other side is adjustable like above. In fact, this adjustable one goes on the fuselage side, but that does not matter.

So, 4 in total for the bottom, m3 threaded. 8 for the top, solid with a hole for the bracing wire.

Wow, many hours of fun coming up!