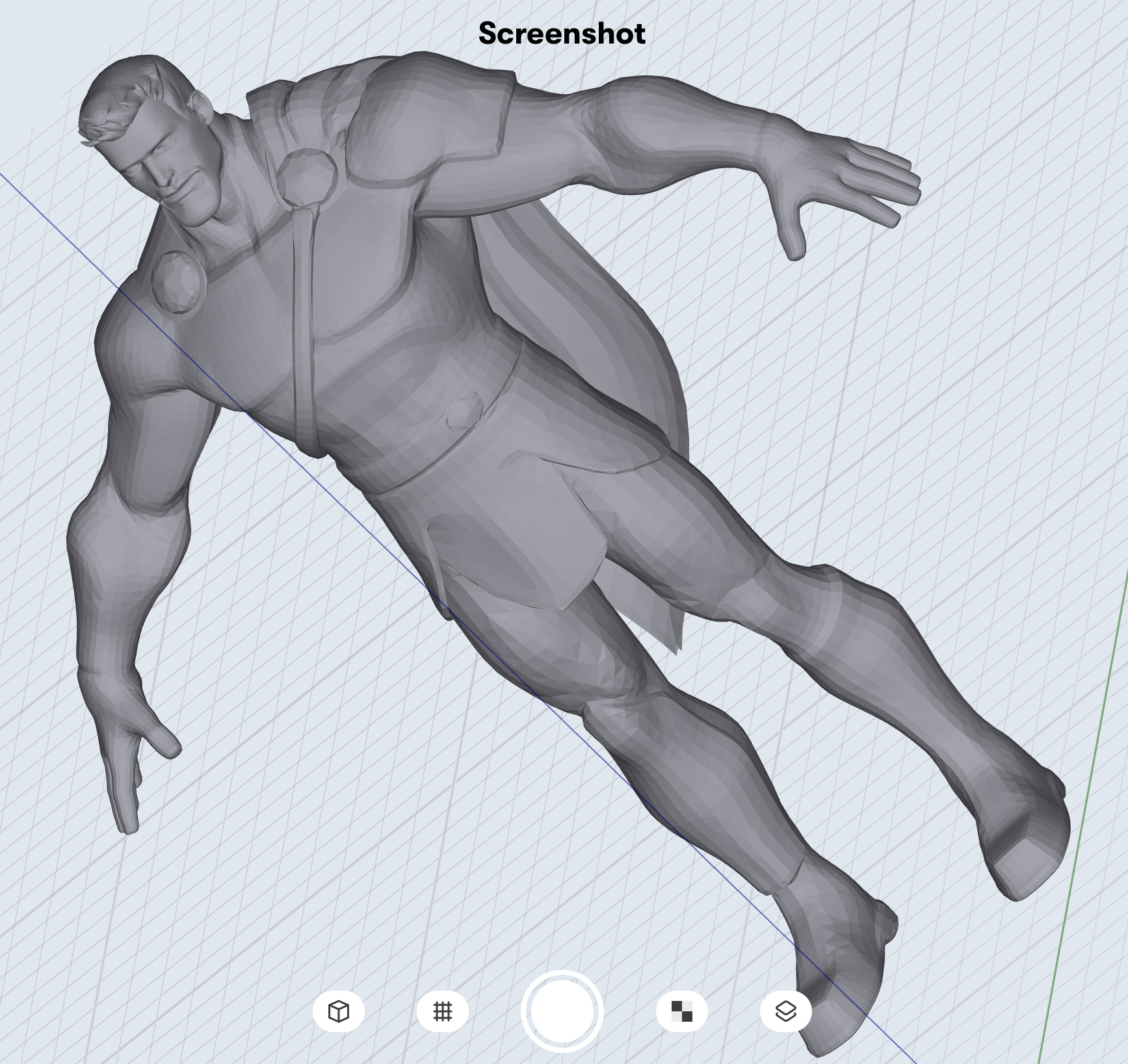

TLAR (that looks about right)

That’s the way we used to (and still mostly do) design our stuff. If it looks right, it will fly right. Works since the days of the Wright brothers (and all those that went before and came after them.) However, fun has to be had! I need to sort of start thinking about the wings … Read more