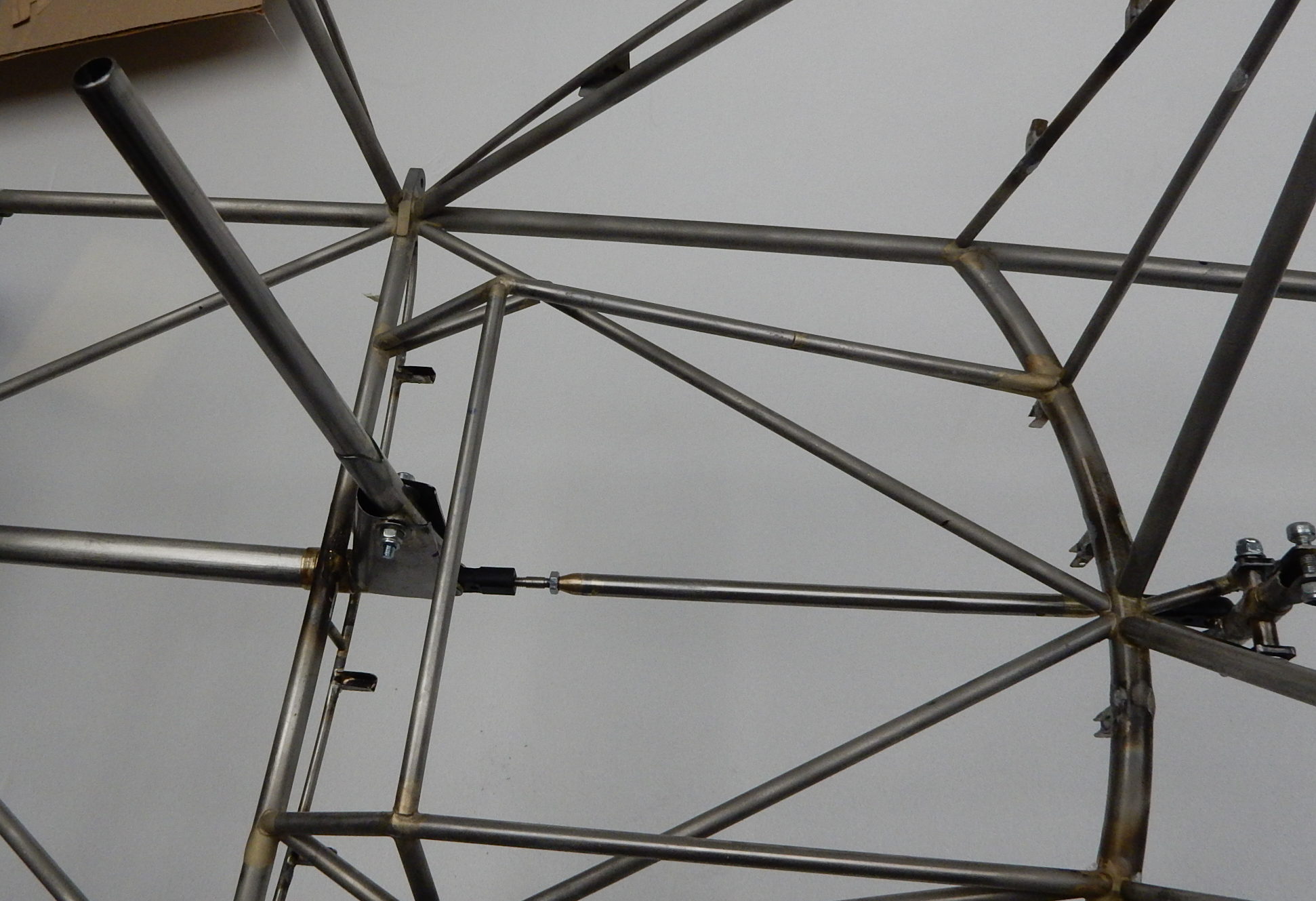

Rear end skinning

The panels for the access to the rear end are made from 0.3 mm stainless steel. The main challenge was working out a method to fit the panels with screws as per full size. After the inevitable ”not fit for use” parts, I think I worked out a method that I can use at the … Read more